Qu'est-ce qu'une batterie au lithium empilée?

Explorez-vous des options pour un système de stockage d'énergie flexible et évolutif? Vous avez probablement entendu le terme "batterie de lithium empilée" et sont curieux de savoir ce que cela signifie, Comment ça marche, Et si c'est la bonne solution pour vos besoins. Ces unités d'alimentation modulaires offrent une approche hautement personnalisable pour développer vos réserves d'énergie, Surtout pour la puissance solaire ou de sauvegarde.

Une "batterie au lithium empilée" Le système fait référence aux modules de batterie au lithium individuels - en utilisant très souvent le phosphate de fer au lithium sûr et durable (Lifepo₄ ou lfp) chimie - qui sont spécialement conçues pour être physiquement empilées les unes sur les autres ou disposées dans une grille dédiée puis interconnectée électriquement. Cette philosophie de conception permet l'expansion facile de votre capacité totale de stockage d'énergie (mesuré en kilowattheures, kWh) et, si nécessaire, peut également être configuré pour atteindre différentes tensions système. Ils sont une pierre angulaire des systèmes d'énergie solaire moderne, Solutions d'alimentation hors réseau, et sauvegarde d'urgence fiable.

À Gycx Solaire, Nous concevons fréquemment et installons des systèmes en utilisant des batteries au lithium empilées, en particulier les modules de rack de serveur LFP, En raison de l'incroyable flexibilité, évolutivité, et la fiabilité qu'ils offrent à nos clients. Il s'agit de créer une solution de stockage d'énergie qui non seulement répond à vos besoins actuels, mais peut également s'adapter à vos futures demandes d'énergie. Plongeons vos questions spécifiques sur cette technologie.

Les batteries LifePO4 peuvent être empilées?

Vous êtes intéressé par les avantages de Lifepo₄ (Phosphate de fer au lithium ou LFP) Batteries - leur sécurité, longue vie, et forance - et vous vous demandez s'ils se prêtent à une configuration empilée d'économie d'espace. C'est une excellente question, Comme la LFP est en effet un choix de premier plan pour ces systèmes modulaires.

Oui, absolument! De nombreuses batteries LifePo₄ sont spécialement conçues et conçues comme modulaires, unités empilables. Ce facteur de forme est en fait une correspondance parfaite pour la chimie LFP. La sécurité inhérente et la stabilité thermique de la LFP le rendent bien adapté à des configurations densément emballées. Les fabricants tirent parti de ces avantages pour créer des systèmes de stockage d'énergie évolutifs et fiables où les modules LFP individuels peuvent être physiquement empilés et connectés électriquement pour atteindre la capacité et la tension souhaitées. Ceci est très courant dans les applications de stockage d'énergie solaire résidentielle et commerciale.

Plonger plus profondément: Pourquoi LFP excelle dans les conceptions empilables

LifePo₄ Chemistry est un excellent ajustement pour les systèmes de batterie empilables pour plusieurs raisons:

- Sécurité inhérente: La LFP est l'une des chimies au lithium-ion les plus sûres. Il a un seuil de fuite thermique plus élevé (ce qui signifie que c'est beaucoup moins sujet à surchauffer et à prendre feu si stressé) par rapport à d'autres types de lithium communs comme NMC ou LCO. Il s'agit d'un avantage critique lorsque les modules sont placés à proximité dans une pile ou un rack.

- Longue durée de vie: Les batteries LFP sont réputées pour leur longue durée de vie du cycle, Souvent capable de milliers (Par exemple, 3,000 à 6,000+, même 10,000 pour certains) de cycles de charge de charge profonde tout en conservant une capacité significative. Cela les rend idéaux pour les systèmes de stockage d'énergie conçus pour durer de nombreuses années, comme ceux associés à l'énergie solaire.

- Stabilité thermique: LFP fonctionne bien sur une plage de température raisonnablement large et est moins sensible aux fluctuations de température que certaines autres chimies, simplifier la gestion thermique dans une configuration empilée.

- Pas de cobalt: La chimie LFP n'utilise pas de cobalt, un minéral associé aux préoccupations d'approvisionnement éthique et à la volatilité des prix. C'est un facteur de plus en plus important pour les solutions énergétiques durables.

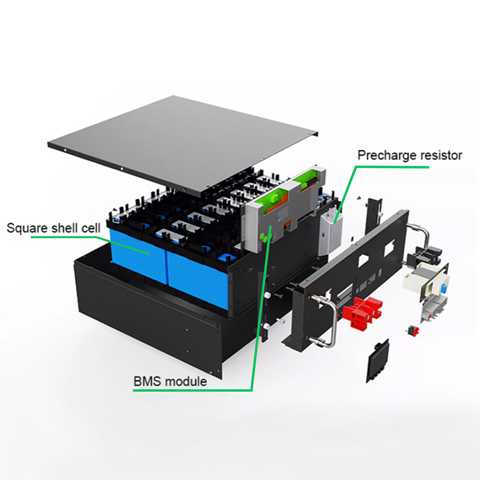

- BMS intégré: Les modules LFP empilables réputés sont toujours livrés avec leur propre système de gestion de batterie intégré (GTC1. ). Ce BMS protège les cellules de chaque module, surveille leur santé, et communique souvent avec d'autres modules et l'onduleur du système principal pour assurer un fonctionnement sûr et optimisé de toute la pile.

À Gycx Solar, Lorsque nous proposons une solution de batterie empilable, Nous recommandons presque exclusivement la technologie LFP. Qu'il s'agisse de modules de style de rack de serveurs qui glissent dans une armoire ou autrement des conceptions d'empilement construites, LFP offre la sécurité, longévité, et performances dont nos clients ont besoin pour un stockage fiable d'énergie solaire. Nous avons connu un succès incroyable en utilisant ceux-ci pour adapter parfaitement les tailles de système, de la sauvegarde de la maison modeste aux plus grandes configurations commerciales.

Comment empiler les batteries pour augmenter la tension?

Vous avez votre modulaire, piles empilables, et votre projet nécessite une tension système plus élevée qu'un seul module fournit. Comment connectez-vous correctement ces unités pour atteindre cette tension augmente en toute sécurité et efficacement? La clé réside dans une configuration électrique spécifique appelée connexion série.

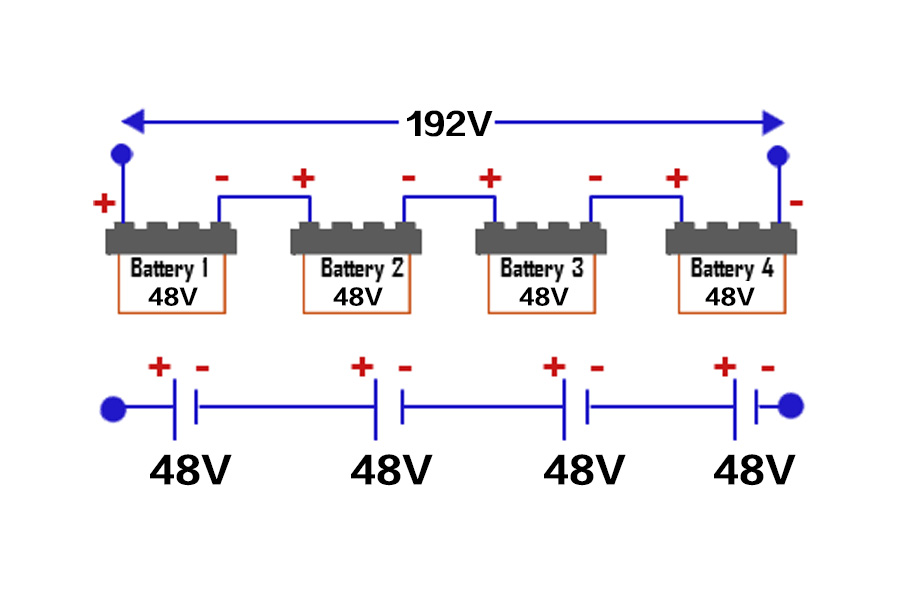

À "empiler" (ou, plus précisément, se connecter électriquement) batteries pour atteindre une tension totale plus élevée, Vous devez les câbler en série. Cela implique de connecter le positif (+) Terminal du premier module de batterie au négatif (-) Terminal du deuxième module de batterie. Alors, le positif (+) le terminal du deuxième module se connecte au négatif (-) terminal du troisième, et ainsi de suite, former une chaîne.

La tension globale mesurée à travers la borne positive ouverte du tout premier module et la borne négative ouverte du tout dernier module de la chaîne seront la somme des tensions de module individuel. Il est absolument crucial d'utiliser des modules identiques (même chimie, capacité,et idéalement, état de charge) Lors de la connexion en série pour éviter les déséquilibres et les dommages potentiels.

Plonger plus profondément: Les principes des connexions de la batterie de la série

Comprendre comment connecter correctement les batteries en série est fondamental pour atteindre une tension plus élevée souhaitée:

- Le chemin de connexion: Imaginez l'électricité qui s'écoule de la terminale positive de la première batterie, à travers votre charge (ou Charger), puis besoin de revenir à la borne négative de cette même batterie pour terminer le circuit. Dans une connexion en série, Vous faites essentiellement le courant qui traverse chaque batterie l'une après l'autre. Donc, le positif de la batterie 1 se connecte au négatif de la batterie 2, le positif de la batterie 2 au négatif de la batterie 3, et ainsi de suite. Le principal terminal positif de votre système est tiré de la première batterie positive, Et le principal négatif de la dernière batterie négative.

- La tension s'additionne: Chaque batterie de la série contribue à sa tension au total. Donc, Si vous avez trois modules de 12 volts, La tension totale du système devient 12V + 12V + 12V = 36 volts. Si vous avez quatre 48 volts (LFP nominal) modules que vous devez série pour un système de tension plus élevée (Moins commun pour l'énergie solaire résidentielle typique qui normalise sur 48 V Banques généralement construites en parallèle des modules 48V, mais possible pour des applications spécifiques), vous obtiendriez 48v x 4 = 192v.

- Capacité (Ampli, Ah) Reste le même: Lorsque les batteries sont connectées en série, La capacité totale d'ampli-heure de la chaîne est égale à la capacité d'ampli-heure du module unique la plus faible dans cette chaîne. Par exemple, Si vous série trois batteries 12V 100h, Vous obtenez une banque de batterie 36V 100h. L'AH ne s'additionne pas.

- Énergie totale (kWh) Augmentation: Depuis des kilowattheures (kWh) = (Capacité totale de tension x ampli) / 1000, En augmentant la tension tandis que la capacité AH de la chaîne (par module) reste constant, l'énergie totale stockée (kWh) de la banque fait augmenter.

- Utiliser des modules identiques: Ceci est essentiel pour la sécurité et les performances. Utilisez toujours des batteries de la même chimie (Par exemple, All LFP), la même tension nominale, la même capacité Ah, le même âge, et de préférence du même fabricant et du même lot, et à un état de charge similaire avant de se connecter. Les modules incompatibles peuvent entraîner un module surfacturé ou surfacturé par rapport aux autres, causant des dommages ou même des conditions dangereuses.

- Considérations BMS: Pour les chaînes connectées en série, Surtout avec les batteries lithium-ion, le système de gestion de batterie (GTC) est vital. Chaque module peut avoir son propre BMS, Mais pour les chaînes de tension plus élevée, s'assurer que l'équilibrage et la protection des cellules peuvent être gérés efficacement à travers le chaîne entière est crucial. Cela peut impliquer un maître BMS supervisant les unités BMS du module individuel ou à l'aide de modules spécialement conçus pour le fonctionnement des séries à haute tension.

Tandis que bon nombre de nos systèmes résidentiels et commerciaux légers du GYCX utilisent des modules LFP 48 V connectés dans parallèle augmenter la capacité, Nous comprenons les principes et les exigences pour les connexions en série lorsque des applications spécifiques exigent des tensions de bus CC plus élevées.

Est-il sûr d'empiler les batteries?

La sécurité est toujours la priorité absolue lorsqu'il s'agit de tout système électrique, et les batteries ne font pas exception. Donc, Quand vous entendez parler de "piles empiler," La question immédiate est: Est-ce une pratique sûre? La réponse est une entreprise, Conditionnel "Oui."

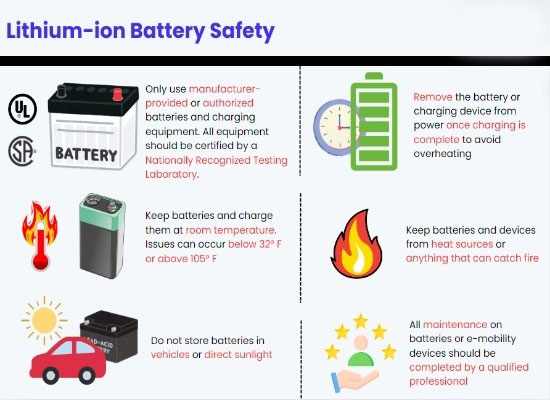

C'est Seulement en toute sécurité pour empiler les batteries qui sont explicitement conçues et fabriquées pour être empilables. Ces modules de batterie spécialement conçus intègrent des caractéristiques spécifiques pour la stabilité mécanique (comme des enveloppes ou des conceptions imbriquées pour un rayonnage sécurisé), Assurer une isolation électrique appropriée entre les unités pour éviter les courts-circuits, et permettre une gestion thermique adéquate (flux d'air) Entre les unités empilées. Tenter d'empiler arbitrairement les batteries qui ne sont pas conçues à cet effet - par exemple, Il suffit d'empiler des batteries de voiture standard ou des cellules cylindriques lâches - est extrêmement dangereux et ne devrait jamais, jamais fini.

Plonger plus profondément: Sécurité par conception dans des systèmes de batterie empilables

Les fabricants réputés investissent massivement dans la conception de systèmes de batterie empilables avec la sécurité comme principe de base:

- Conçu pour la stabilité: Les modules destinés à l'empilement ont souvent des fonctionnalités comme des rainures, lèvres, ou des mécanismes de verrouillage qui s'assurent en toute sécurité les uns sur les autres, Empêcher de déplacer ou de renverser. Alternativement, beaucoup "empilables" systèmes, Comme les batteries de rack de serveurs, sont conçus pour être installés dans des racks ou des armoires métalliques robustes qui fournissent le support structurel et la stabilité primaires.

- Sécurité électrique: Les bornes sur les modules empilables sont généralement encastrées, enveloppé, ou conçu avec des connecteurs spécifiques pour empêcher le contact accidentel et les courts circuits lorsque les modules sont placés à proximité ou pendant l'installation. Le câblage interne et les bus utilisés pour interconnecter les modules sont également conçus pour les courants et tensions attendus.

- Gestion thermique: Les batteries génèrent de la chaleur pendant le fonctionnement. Les conceptions empilables doivent permettre un flux d'air suffisant autour et entre chaque module pour dissiper efficacement cette chaleur. La ventilation obstruée peut entraîner une surchauffe, qui dégrade la durée de vie de la batterie et peut devenir un risque de sécurité. Certains systèmes de rack fermés pourraient même incorporer des ventilateurs pour le refroidissement à l'air forcé.

- Protection BMS intégrée: Comme nous l'avons souligné, Chaque module d'un système de batterie au lithium empilable moderne (Surtout LFP) aura son propre BMS sophistiqué. Ceci est une couche de sécurité critique, protéger contre les suraliments, trop décharger, surintensité, court-circuites, et des températures extrêmes au niveau du module. Dans une pile bien conçue, Ces unités BMS communiquent souvent entre elles ou un contrôleur central pour assurer un fonctionnement coordonné et sûr de toute la banque.

- Considérations de poids & Limites du fabricant: Les fabricants fournissent des directives claires sur le nombre de modules peuvent être empilés en toute sécurité directement les uns sur les autres (Si conçu pour l'empilement direct) ou la capacité de poids maximale pour des systèmes de rayonnage spécifiques. Dépasser ces limites peut compromettre la stabilité et la sécurité.

- Certificats: Recherchez toujours des systèmes de batterie empilables qui ont subi des tests de sécurité rigoureux et des certifications pertinentes, comme ul 1973 (Norme pour les batteries à utiliser dans les applications stationnaires) et ul 9540 (Norme pour les systèmes et équipements de stockage d'énergie).

Gycx Solar Story: "Nous disons toujours à nos clients, "Ne vous contentez pas d'acheter des modules de batterie et de les empiler!' Par exemple, Nous avons récemment conçu un système pour un client utilisant des batteries de rack de serveurs LFP. Nous avons spécifié une armoire particulièrement sismique, assuré d'espacement approprié entre les modules pour le flux d'air selon la fiche technique du fabricant, et méticuleusement inversé toutes les connexions électriques. Cette attention aux détails de «l'empilement», dans une enceinte d'ingénierie, est la clé d'une installation à long terme sûre et fiable."

Est-il sûr d'empiler les piles les unes sur les autres?

Cette question arrive au cœur de l'acte physique d'empilement. Nous avons établi que seulement conçu Les batteries empilables sont sûres, Mais qu'est-ce que cela signifie en termes de placement littéralement un module de batterie lourd sur un autre?

Oui, Il peut être sûr d'empiler certains modules de batterie directement les uns sur les autres, mais seulement si Ils sont spécialement conçus par le fabricant pour une telle empilement physique direct. Ces modules auront des enveloppes renforcées et des caractéristiques de verrouillage pour assurer la stabilité et la bonne répartition du poids. Cependant, de nombreux systèmes appelés "empilables," Comme les batteries de rack de serveur LFP communes, sont en fait conçus pour être soutenus individuellement par des étagères ou des rails dans un rack ou une armoire dédiée, Plutôt que d'avoir le poids total des modules supérieurs reposant directement sur les boîtes de baisse à moins que la conception ne le permette explicitement. Consultez toujours les spécifications du fabricant.

Plonger plus profondément: Considérations physiques pour l'empilement

Lorsque vous envisagez de placer physiquement les modules de batterie les uns sur les autres, Voici ce qui compte:

- Conception et intention du fabricant: C'est primordial. La fiche technique ou le manuel d'installation du produit indiquera clairement si l'empilement direct est autorisé et, le cas échéant, Combien d'unités de haut, et toute exigence d'orientation ou de verrouillage spécifique. Si ce n'est pas mentionné, Supposons qu'il n'est pas sûr pour l'empilement direct sans support supplémentaire.

- Résistance au boîtier et capacité de chargement: Les modules conçus pour l'empilement direct ont des enveloppes conçues pour soutenir le poids des unités au-dessus d'eux sans déformer ou compromettre les composants internes.

- Mécanismes de verrouillage: De nombreux modules d'empilement direct ont des caractéristiques physiques (Par exemple, rainures, onglets, broches d'alignement) qui les verrouille ensemble, les empêcher de glisser ou de se déplacer. Ceci est crucial pour la stabilité, en particulier dans les zones sujettes aux vibrations ou à l'activité sismique.

- Répartition du poids: Assurer la surface sur laquelle la pile est placée est le niveau et peut supporter le poids concentré total.

- Ventilation et flux d'air: Même avec des conceptions d'empilement direct, Les fabricants tiennent compte du flux d'air nécessaire. Assurez-vous que ces voies ne sont pas obstruées. Certains conceptions pourraient avoir des canaux d'air intégrés qui s'alignent lorsqu'ils sont empilés.

- Batteries de rack de serveurs - un "empilé commun" Exemple: Les batteries de rack de serveurs LFP que GYCX Solar utilise fréquemment sont un excellent exemple d'un système souvent appelé «empilable." Tandis qu'ils sont placés physiquement l'un au-dessus de l'autre Dans une armoire ou un rack de 19 pouces, Chaque module est généralement pris en charge par son propre ensemble de rails ou d'une étagère. Le rack lui-même fournit le support structurel principal et assure un espacement et un alignement appropriés. Ceci est différent des modules conçus pour supporter tout le poids des autres directement sur leur boîtier.

- La sécurité d'abord: S'il y a un doute sur le fait que les modules peuvent être directement empilés ou comment le faire en toute sécurité, toujours Reportez-vous à la documentation officielle du fabricant ou consultez un installateur qualifié comme GYCX Solar. Un empilement physique inapproprié peut conduire à l'instabilité, dommage, et de graves risques de sécurité.

"Batteries au lithium empilées," en particulier ceux qui utilisent la chimie LifePo₄ et conçus avec la modularité et la sécurité à l'esprit, Offrez une approche puissante et flexible du stockage d'énergie. Que vous cherchiez à augmenter la tension par le biais de connexions en série ou de renforcer la capacité en parallèle des modules, Il est essentiel de comprendre les principes de conception et d'adhérer aux directives de sécurité.

À Gycx Solar, Nous sommes des experts dans la conception et l'installation de solutions de stockage d'énergie évolutives à l'aide de haute qualité, Systèmes de batterie au lithium empilables en toute sécurité. Si vous avez des questions sur la façon dont une banque de batterie modulaire peut répondre à vos besoins en énergie solaire ou en puissance de sauvegarde, Nous vous invitons à nous contacter. Construisons un avenir énergétique résilient pour vous, un module bien emparé à la fois.

Découvrez les termes liés à la batterie tels que le système de gestion de la batterie pour une meilleure compréhension comparative des concepts de données liées à la batterie au lithium. Cela vous aidera à choisir un produit qui convient mieux à vos besoins. ↩