Compreender o conteúdo de lítio em um 1 Bateria KWH: Benefícios para sistemas de baterias de lítio empilháveis

A tecnologia de íons de lítio alimenta tudo, desde veículos elétricos a sistemas de armazenamento de energia renovável. Mas você já se perguntou quanto lítio está em um 1 Bateria KWH? Neste artigo, Exploramos os fundamentos por trás do conteúdo de lítio em sistemas de bateria, Discuta as implicações para o armazenamento de energia, e explique por que soluções modulares modernas - como Baterias de lítio empilháveis- estão mudando o jogo.

Dados e recomendações técnicas são corroboradas por especialistas do setor e reforçadas por números da Wikipedia's Bateria de íon de lítio página.

Introdução

As baterias de íons de lítio são a pedra angular dos dispositivos de energia portáteis e renováveis de hoje. Com eletrificação em ascensão, Determinar a quantidade exata de lítio em uma célula de bateria é importante para a estimativa de custos, Planejamento de sustentabilidade, e avaliação geral de desempenho. Para aplicações solares e armazenamento de grade, Muitos instaladores e engenheiros agora estão gravitando em direção a soluções de armazenamento modulares e escaláveis, como Baterias de lítio empilháveis.

Este artigo descompacta a quantidade de lítio em um 1 Bateria KWH, explica os cálculos por trás das estimativas, e ilustra como os projetos modernos de baterias estão aproveitando esses dados para otimizar o desempenho e a sustentabilidade. Também faremos comparações com as construções tradicionais de bateria e apontaremos por que inovações de produtos como o 48V rack de montagem em bateria de lítio e Armazenamento de bateria empilhável são essenciais no mercado de energia de hoje.

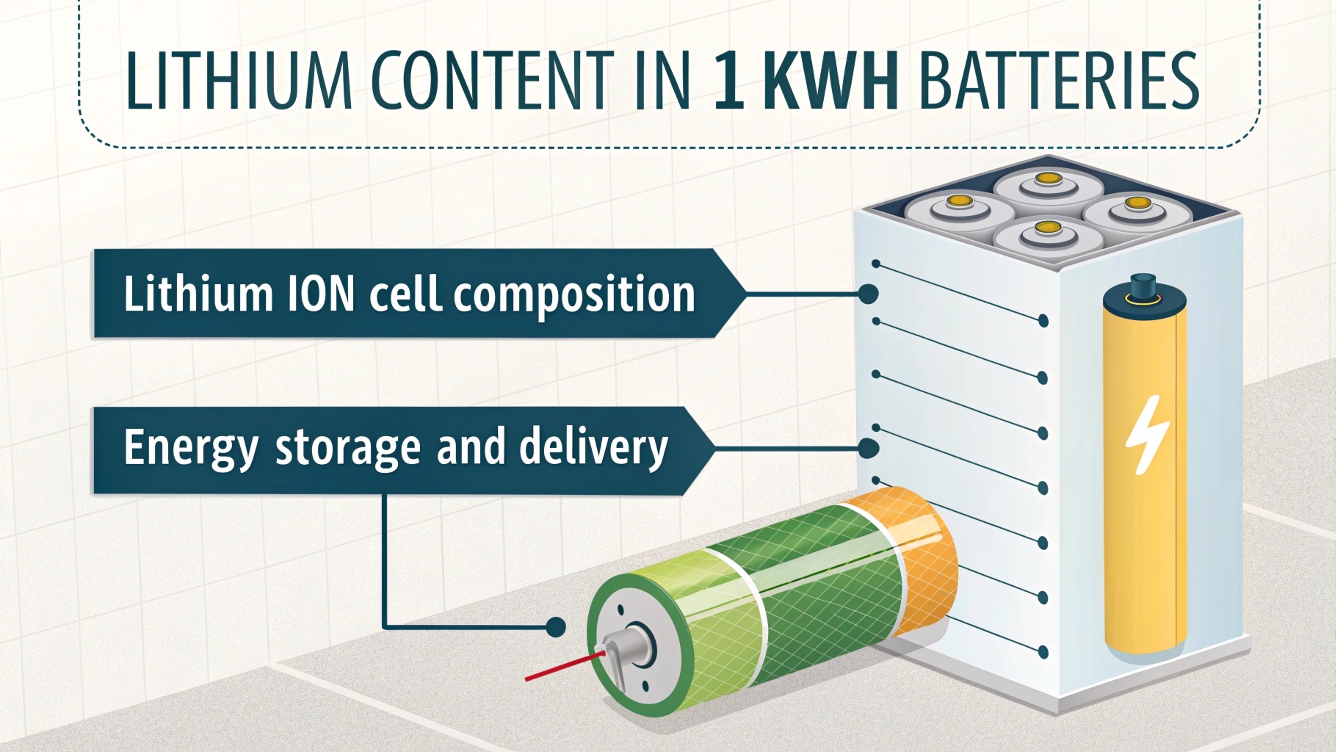

Lítio em 1 KWH baterias: O básico

Para entender o conteúdo de lítio, É importante entender a composição de uma célula típica de íon de lítio. Nem todo o lítio em uma bateria é "lítio livre" - a maioria existe dentro de compostos químicos complexos que facilitam o armazenamento e entrega de energia.

Quanto lítio existe?

Relatórios e análises do setor sugerem que, Para uma bateria típica de íon de lítio, aproximadamente 0.3 para 0.6 quilogramas (300–600 gramas) de compostos de lítio são usados por kWh de capacidade de armazenamento. No entanto, A quantidade real de metal puro de lítio é muito menor. Estimativas de análises profissionais indicam que há aproximadamente 80 para 120 gramas de lítio puro em um 1 Bateria KWH, dependendo dos parâmetros de química e design específicos.

As discrepâncias em números vêm de:

- Variações nas químicas da bateria (Por exemplo, Fosfato de ferro de lítio vs. Níquel manganês óxido de cobalto)

- Diferenças na construção celular e eficiências materiais

- Avanços na fabricação esse menor uso de lítio, mantendo ou aumentando a densidade de energia

Para uma quebra técnica mais detalhada, Veja a da Wikipedia Bateria de íon de lítio página.

Por que isso importa

A quantidade de lítio usada nas baterias não apenas influencia os custos de produção, mas também tem implicações ambientais e geopolíticas significativas. Dada a rápida expansão em energia renovável e veículos elétricos, A compreensão do uso de lítio é fundamental para o gerenciamento sustentável da escala e da cadeia de suprimentos.

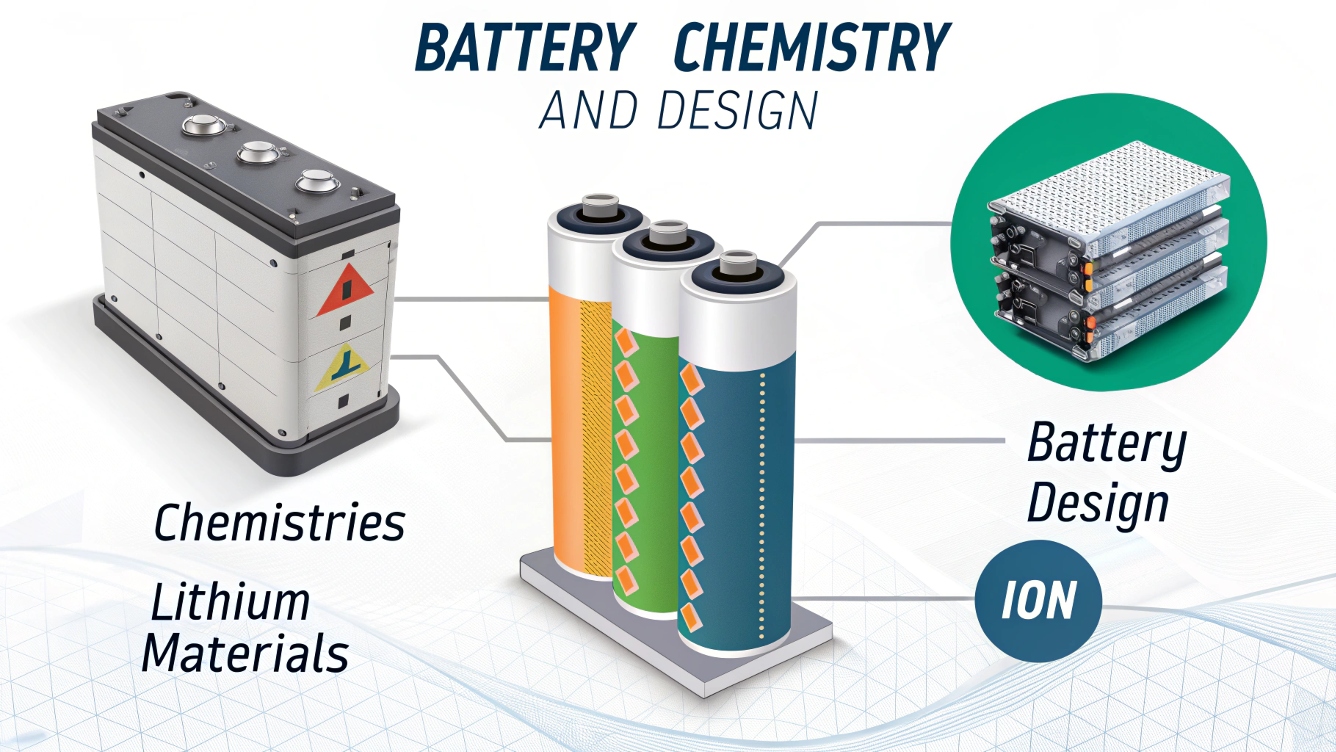

O papel da química e design da bateria

O desempenho da bateria está bem ligado ao tipo de química de íons de lítio implantada. Diferentes materiais e projetos usam quantidades variadas de lítio. Vamos examinar alguns dos projetos de bateria comuns:

Considerações de cátodo e ânodo

Materiais de cátodo:

Muitas baterias de íon de lítio usam óxido de cobalto de lítio (LCO), Óxido de cobalto de níquel de níquel de lítio (NMC), ou fosfato de ferro de lítio (LifePo₄) como materiais catódicos. A porcentagem de lítio em peso difere um pouco entre esses tipos. Por exemplo, As baterias da vida são conhecidas por segurança e longevidade, mas contêm menos lítio em comparação com as variantes NMC.Composição do ânodo:

O ânodo é frequentemente feito de grafite, intercalação de íons de lítio durante o custo. Embora a grafite não contenha lítio, O design geral da bateria otimiza a quantidade de lítio que é ciclada entre eletrodos.

Melhorias de eficiência

Técnicas modernas de fabricação refinaram como o lítio é usado em células de bateria. Através da inovação, Os designers estão reduzindo o excesso de material e maximizando a densidade de energia. Essa eficiência ajuda não apenas a reduzir os custos gerais, mas também a mitigar a pegada ambiental da mineração de lítio.

Esses avanços têm implicações significativas para produtos como Baterias de lítio empilháveis. Seu design alavanca a construção modular que pode incorporar as mais recentes melhorias na eficiência do uso de lítio, permitindo melhor escalabilidade e longevidade.

Aplicação em sistemas de armazenamento de energia renovável

Uma área em que a compreensão do conteúdo de lítio é particularmente importante é o armazenamento de energia solar. À medida que a energia solar se torna mais difundida, Clientes e instaladores precisam saber não apenas quanta energia é armazenada, mas também os aspectos de sustentabilidade do meio de armazenamento.

Custo e sustentabilidade

Impacto de custo:

O preço do lítio é um componente importante do custo geral de um sistema de bateria. Sabendo disso a 1 A bateria KWH pode exigir apenas em torno 80 para 120 Gramas de lítio puro permitem que os fabricantes estimam melhor os custos de produção. Esse custo-efetividade é crucial ao projetar sistemas para instalações solares domésticas e comerciais.Considerações ambientais:

O uso reduzido de lítio é benéfico para o meio ambiente. Com padrões de reciclagem mais apertados e práticas aprimoradas da cadeia de suprimentos, Menos lítio por kwh significa menor impacto ambiental. Esta é uma situação em que todos saem ganhando para os fabricantes e usuários finais que buscam tecnologias mais verdes.

No GYCX Solar, a integração de soluções de armazenamento de alta qualidade-como nosso Armazenamento de bateria empilhável Os sistemas - estão enraizados no uso das químicas de bateria mais eficientes para otimizar a sustentabilidade e o desempenho.

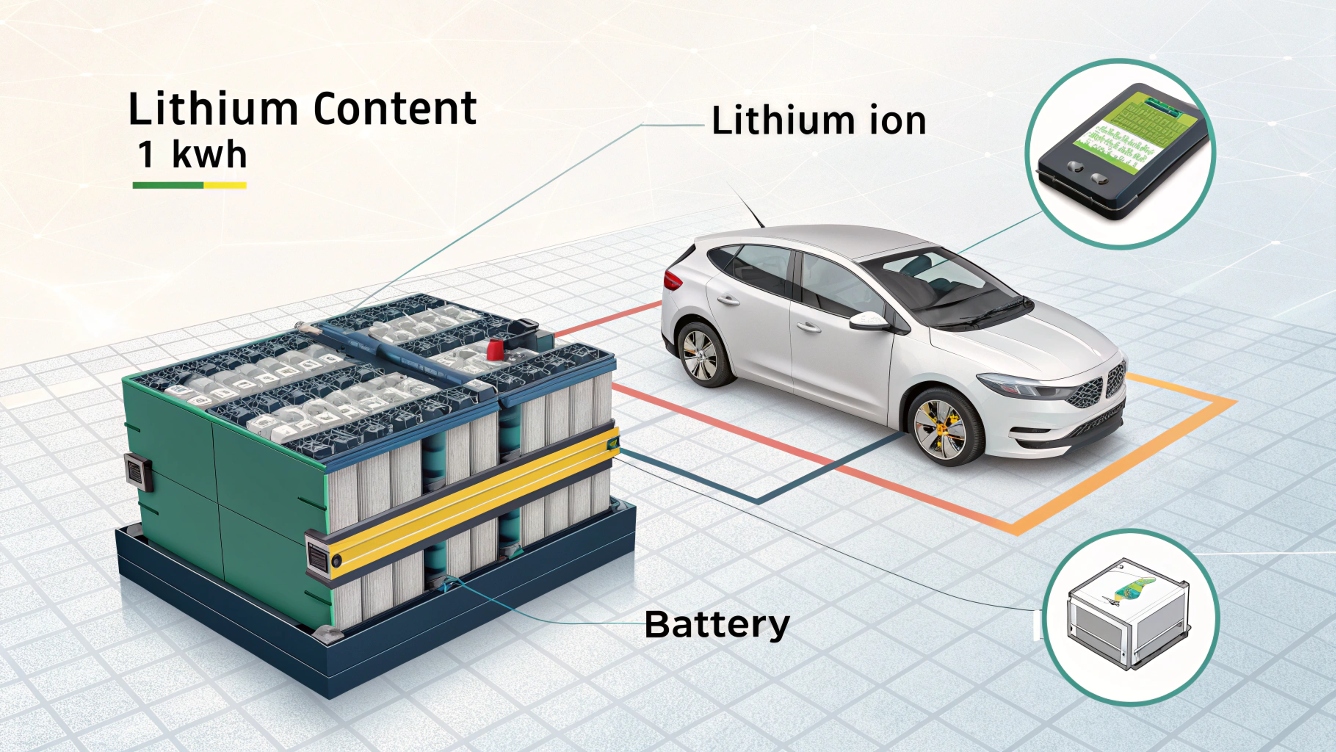

Aparelhamento técnico: Calculando o teor de lítio

Compreender como os profissionais estimam o teor de lítio nas células da bateria envolve uma combinação de análise química e estimativas de engenharia.

Estimativa passo a passo

Determinar a densidade de energia:

A densidade de energia em baterias de íons de lítio geralmente é dada em watt-horas por quilograma (W/kg). Os fabricantes normalmente alcançam em qualquer lugar de 150 para 250 WH/KG em produtos comerciais.Estimar massa de material total:

Para um 1 Bateria KWH, a massa geral de materiais ativos pode variar de 4 para 6.5 quilogramas. Fora desta massa total, A fração de lítio é relativamente pequena.Aplique porcentagem de lítio:

Com base em dados empíricos, Aproximadamente 2-3% da massa da bateria é pura lítio. Isso significa isso:- Para um 1 KWH Battery pesando 5 kg, O teor puro de lítio é de cerca de 100 a 150 gramas.

- Modelos mais precisos podem refinar esse número para cerca de 80 a 120 gramas com base nas otimizações de design de células.

Tabela de comparação de dados

| Parâmetro | Valor estimado | Notas |

|---|---|---|

| Densidade energética | 150–250 wh/kg | Varia de acordo com a química da bateria |

| Massa total de célula ativa | 4–6,5 kg por 1 kWh | Inclui eletrodos e eletrólitos |

| Porcentagem de lítio puro | Aproximadamente 2-3% | Depende de técnicas de design e fabricação |

| Lítio puro estimado | 80–120 gramas | Para um padrão 1 Bateria KWH |

Fonte: Estimativas de análises do setor e dados técnicos resumidos na Wikipedia's Bateria de íon de lítio entrada.

Integração de soluções modernas de produtos

Os sistemas de energia renovável modernos integram mais do que apenas células de bateria - eles exigem avançado, projetos modulares para lidar com cargas variáveis e expansão futura. No GYCX Solar, Oferecemos várias variantes de produtos que incorporam essa filosofia modular.

Baterias de lítio empilháveis

Nosso Baterias de lítio empilháveis são projetados para escalabilidade. Eles permitem a adição de mais módulos de bateria à medida que as necessidades de energia evoluem, tornando -os ideais para sistemas solares residenciais e comerciais.

48V rack de montagem em bateria de lítio

Para instalações onde o espaço e a facilidade de manutenção são críticos, nosso Bateria de lítio de montagem em rack Fornece uma solução robusta com engenharia precisa para maximizar o desempenho e a segurança.

Armazenamento de bateria empilhável

Outra oferta -chave é a nossa Armazenamento de bateria empilhável sistema, que foi projetado para se integrar perfeitamente em configurações de energia renovável em larga escala. Seu design não apenas otimiza os protocolos de carregamento, mas também reforça a facilidade de expansão do sistema.

Vinculando essas páginas de produto em nossos artigos, Criamos um ecossistema robusto que suporta a navegação do cliente e o SEO interno - uma estratégia crucial no cenário digital competitivo de hoje.

Implicações do mundo real e perspectiva futura

Compreender o conteúdo de lítio de uma bateria não é apenas um exercício acadêmico-ele tem implicações no mundo real para tecnologias futuras. Como veículos elétricos, armazenamento em grade, e energia portátil se torna ainda mais crítica, Os avanços na química da bateria continuarão a desempenhar um papel fundamental.

Tendências emergentes

Aumento da densidade energética:

A pesquisa em andamento tem como objetivo obter mais densidades de energia com menos lítio. Isso significa que as baterias futuras podem exigir quantidades ainda mais baixas de lítio por kWh enquanto oferecem desempenho superior.Reciclagem e sustentabilidade:

Métodos de reciclagem aprimorados recuperarão mais lítio de baterias usadas. Isso não apenas reduz o desperdício, mas também diminui a necessidade de nova mineração de lítio, Alinhando -se com objetivos globais de sustentabilidade.Integração do sistema modular:

Sistemas modulares como o nosso Baterias de lítio empilháveis estão na vanguarda desta evolução. Sua natureza escalável significa que os sistemas podem ser facilmente atualizados à medida que as tecnologias de bateria melhoram, Garantir que as instalações de energia renovável permaneçam de última geração ao longo do tempo.

Opiniões de especialistas

Especialistas do setor enfatizam que a melhor eficiência e o uso reduzido da matéria -prima são essenciais para o futuro da fabricação de baterias. Vários trabalhos de pesquisa destacam que mesmo uma pequena redução no uso de lítio por kWh pode ter um impacto maciço nos requisitos de recursos globais. À medida que mais dados se tornam disponíveis, Esperamos que esses números evoluam, cimentando ainda mais a importância do design sustentável em sistemas de armazenamento de energia.

Conclusão

Determinando quanto lítio está em um 1 Bateria KWH revela muito mais do que apenas números brutos - fornece uma janela para a eficiência e sustentabilidade da tecnologia de armazenamento de energia moderna. Com estimativas sugerindo em torno 80 para 120 gramas de lítio puro por 1 kWh, Os avanços na química e no design da bateria continuam a otimizar o equilíbrio entre desempenho e uso de recursos.

Produtos como Baterias de lítio empilháveis, 48V rack de montagem em bateria de lítio, e Armazenamento de bateria empilhável exemplificar como modular, Soluções escaláveis estão revolucionando a paisagem de armazenamento de energia. No GYCX Solar, Estamos comprometidos em fornecer soluções avançadas de armazenamento que não são apenas eficientes, mas também projetadas com o futuro em mente.

Ao entender os detalhes complexos por trás do conteúdo de lítio e aplicar esse conhecimento aos modernos sistemas de bateria, As partes interessadas-dos proprietários de imóveis a usuários industriais em larga escala-podem tomar decisões informadas que beneficiam o desempenho e a sustentabilidade. Com uma abordagem proativa da tecnologia e da administração ambiental, O futuro do armazenamento de energia é brilhante e cheio de inovação.