什么是堆积的锂电池?

您是否正在探索灵活且可扩展的储能系统的选项? 您可能已经听过“堆叠锂电池的一词”" 并对它的含义感到好奇, 它如何工作, 如果这是满足您需求的正确解决方案. 这些模块化功率单元提供了一种高度可定制的方法来建立您的能源储备, 特别是对于太阳能或备用电源.

一个堆叠的锂电池" 系统是指各个锂电池模块 - 经常使用安全且持久的磷酸锂 (LifePo₄或LFP) 化学 - 专门设计的是彼此物理堆叠或在专用架子上排列,然后进行电连接. 这种设计理念可以轻松扩展您的总能源存储容量 (以千瓦时为单位, 千瓦时) 和, 如果需要的话, 也可以配置为实现不同的系统电压. 它们是现代太阳能系统的基石, 离网功率解决方案, 和可靠的紧急备份.

在 吉克斯太阳能, 我们经常使用堆叠的锂电池设计和安装系统, 特别是LFP服务器机架模块, 由于灵活性令人难以置信, 可伸缩性, 他们为我们的客户提供了可靠性. 这是关于创建一种储能解决方案,该解决方案不仅满足您当前的需求,而且还可以适应您未来的能源需求. 让我们深入研究您对这项技术的具体问题.

可以将LifePo4电池堆叠吗?

您对LifePo₄的好处感兴趣 (铁磷酸锂或LFP) 电池 - 安全性, 长寿, 和表现 - 您想知道它们是否适合节省空间的配置. 这是一个很好的问题, 由于LFP确实是这些模块化系统的领先选择.

是的, 绝对地! 许多LifePo₄电池专门设计和设计为模块化, 可堆叠的单元. 该外形实际上是LFP化学的完美匹配. LFP的固有安全性和热稳定性使其非常适合密集的配置. 制造商利用这些好处来创建可扩展和可靠的储能系统,在该系统中可以物理堆叠单个LFP模块以实现所需的容量和电压. 这在住宅和商业太阳能存储应用中都很常见.

深入潜水: 为什么LFP在可堆叠的设计中表现出色

LifePo₄Chemistry非常适合可堆叠的电池系统,原因有几个原因:

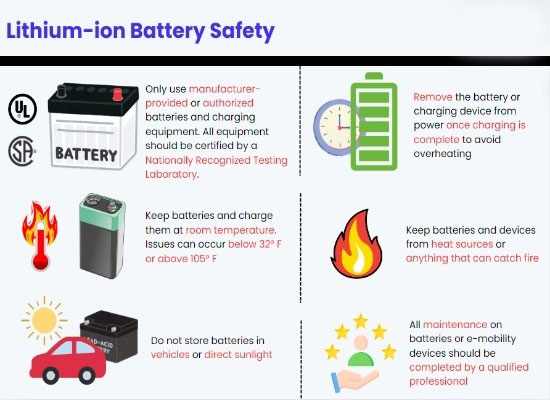

- 固有的安全: LFP是最安全的锂离子化学物质之一. 它具有更高的热失控阈值 (这意味着如果压力很大,它不容易过热和着火) 与其他常见的锂类型(如NMC或LCO)相比. 当模块在堆栈或机架中近距离位置时,这是一个关键的优势.

- 长循环寿命: LFP电池以其长期寿命而闻名, 通常有成千上万的能力 (例如, 3,000 到 6,000+, 甚至 10,000 对于某些人) 深度充电循环,同时保持大量容量. 这使它们非常适合持续多年的能源存储系统, 就像那些搭配太阳能.

- 热稳定性: LFP在合理较宽的温度范围内运行良好,并且对温度波动的敏感性不及其他化学物质, 简化堆叠配置中的热管理.

- 没有钴: LFP化学不使用钴, 与道德采购问题和价格波动相关的矿物. 这是可持续能源解决方案的越来越重要的因素.

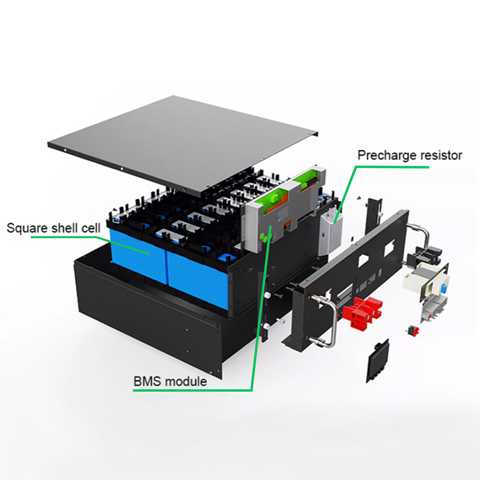

- 集成的BMS: 知名的可堆叠的LFP模块总是带有自己的集成电池管理系统 (电池管理系统1. ). 此BMS保护每个模块的单元格, 监视他们的健康, 并且经常与其他模块和主要系统逆变器进行通信,以确保整个堆栈的安全和优化操作.

在GYCX太阳能, 当我们提出可堆叠的电池解决方案时, 我们几乎只推荐LFP技术. 无论是服务器机架样式模块,都滑入机柜还是其他专用堆叠设计, LFP提供安全性, 长寿, 以及我们的客户需要可靠的太阳能存储. 我们看到了使用这些成功量身定制系统尺寸的令人难以置信的成功, 从适度的家庭备份到较大的商业设置.

如何堆叠电池以提高电压?

你有模块化, 可堆叠电池, 您的项目需要比单个模块提供的更高的系统电压. 您如何将这些单元正确连接在一起以实现安全有效增加的电压? 关键在于特定的电气配置称为串联连接.

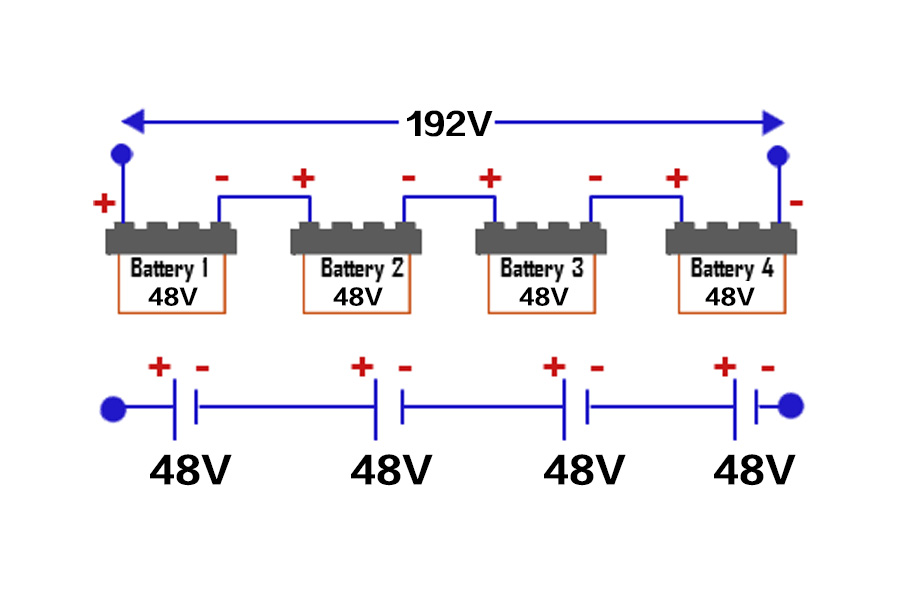

要堆栈" (或者, 更准确, 电连接) 电池以实现更高的总电压, 你必须连接他们 串联. 这涉及连接正面 (+) 第一个电池模块的端子为负 (-) 第二电池模块的端子. 然后, 积极 (+) 第二模块的终端连接到负 (-) 第三端, 等等, 形成链.

跨第一个模块的开放正端子和链中最后一个模块的开放负端子测量的总体电压将是单个模块电压的总和. 使用相同的模块绝对至关重要 (相同的化学, 容量,理想情况下, 充电状态) 串联连接以防止失衡和潜在损害.

深入潜水: 串联电池连接的原理

了解如何串联连接电池对于实现所需的更高电压至关重要:

- 连接路径: 想象电力从第一个电池的正端子流出, 通过您的负载 (或充电器), 然后需要返回同一电池的负端子以完成电路. 在系列连接中, 本质上,您将电流通过每个电池的流动. 所以, 电池的正 1 连接到电池负数 2, 电池的正 2 电池负数 3, 等等. 系统的主要正终端取自第一个电池的正面端子, 以及最后一个电池负面的主要负面.

- 电压加起来: 该系列中的每个电池都为总数贡献了总数. 所以, 如果您有三个12伏模块, 总系统电压变为12V + 12V + 12V = 36 伏特. 如果您有四个48伏 (名义LFP) 您需要用于更高电压系统的模块 (对于典型的住宅太阳能而言,它不太常见,该住宅太阳能在48V银行上标准化,通常是通过平行48V模块而构建的, 但对于特定的应用程序可能), 你会得到48V x 4 = 192V.

- 容量 (放大器小时, 啊) 保持不变: 当电池串联连接时, 字符串的总放大器小时容量等于 单个最低容量模块 在该字符串中. 例如, 如果您系列三串12V 100AH电池, 您会得到36V 100AH电池库. AH不会加起来.

- 总能量 (千瓦时) 增加: 自千瓦时以来 (千瓦时) = (总电压x放大器小时容量) / 1000, 通过增加电压时增加电压 (每个模块) 保持恒定, 总存储的能量 (千瓦时) 银行 做 增加.

- 使用相同的模块: 这对于安全性和性能至关重要. 始终使用相同化学反应的电池 (例如, 所有LFP), 相同的名义电压, 相同的AH容量, 相同的年龄, 最好来自同一制造商和批次, 并在连接之前处于类似的充电状态. 不匹配的模块可能导致一个模块相对于其他模块过度充电或过度递减, 造成损坏甚至危险条件.

- BMS考虑: 用于串联的字符串, 特别是锂离子电池, 电池管理系统 (电池管理系统) 至关重要. 每个模块可能都有自己的BMS, 但是对于更高的电压字符串, 确保可以在整个过程中有效管理细胞平衡和保护 整个字符串 至关重要. 这可能涉及负责监督单个模块BMS单元或使用专门为高压系列操作设计的模块的主BMS.

虽然我们的许多GYCX太阳能住宅和轻型商业系统都使用了48V LFP模块 平行线 增加容量, 当特定应用要求更高的直流总线电压时,我们了解串联连接的原理和要求.

堆叠电池安全吗?

在处理任何电气系统时,安全始终是重中之重, 电池也不例外. 所以, 当您听到“堆叠电池”时," 直接的问题是: 这是安全的做法吗? 答案是公司, 有条件的“是的。"

这是 仅对明确设计和制造的可堆叠的堆叠电池安全. 这些专用的电池模块包含了机械稳定性的特定功能 (像互锁的套管或设计用于安全货架), 确保单元之间正确的电气隔离以防止短路, 并允许足够的热管理 (空气流动) 在堆叠单元之间. 试图任意堆叠不是为此目的而设计的电池 - 例如, 只是堆积标准的汽车电池或松动的圆柱形电池 - 极其危险,永远不要, 永远做.

深入潜水: 可堆叠电池系统中的设计安全

信誉良好的制造商在设计具有安全性的可堆叠电池系统方面投入了大量资金:

- 为稳定而设计: 用于堆叠的模块通常具有诸如凹槽之类的功能, 嘴唇, 或锁定机制,以确保它们牢固地坐在, 防止转移或倒数. 或者, 许多“可堆叠的" 系统, 喜欢服务器架电池, 设计为安装到可提供主要结构支撑和稳定性的稳健金属架或橱柜中.

- 电气安全: 堆叠模块上的终端通常是嵌入式的, 笼罩, 或使用特定连接器设计,以防止在近距离接近或安装期间放置模块时意外接触和短路. 用于互连模块的内部接线和躯体也针对预期电流和电压进行了设计.

- 热管理: 电池在操作过程中产生热量. 可堆叠的设计必须允许每个模块周围和之间足够的气流有效地消散这种热量. 阻塞通气会导致过热, 降低电池寿命并可能成为安全危害. 一些封闭式的机架系统甚至可能会纳入强迫空气冷却的风扇.

- 集成BMS保护: 正如我们强调的, 现代可堆叠锂电池系统中的每个模块 (特别是LFP) 将拥有自己的精致BMS. 这是一个关键的安全层, 防止过度充电, 过度关闭, 过电流, 短路, 和模块水平的极端温度. 在一个精心设计的堆栈中, 这些BMS单元经常相互通信或中央控制器,以确保整个银行的协调和安全运营.

- 体重考虑 & 制造商限制: 制造商提供了明确的指导方针,了解可以将多少模块直接堆叠在彼此的顶部 (如果设计用于直接堆叠) 或特定机架系统的最大重量容量. 超过这些限制会损害稳定性和安全性.

- 认证: 始终寻找经过严格安全测试并获得相关认证的可堆叠电池系统, 例如Ul 1973 (用于固定应用的电池标准) 和ul 9540 (储能系统和设备标准).

GYCX太阳能故事: “我们总是告诉我们的客户, ‘不要只是购买电池模块,然后将它们堆积起来!' 例如, 我们最近为客户设计了一个使用LFP服务器架电池的系统. 我们指定了一个特定的地震柜, 根据制造商的数据表,确保气流模块之间的适当间距, 并精心扭转所有电连接. 对“堆叠”细节的关注, 在工程围栏内, 是安全可靠的长期安装的关键。"

将电池互相堆叠安全吗??

这个问题成为堆叠物理行为的核心. 我们已经确定了 设计 可堆叠的电池安全, 但是,这意味着从字面上将一个重电池模块放在另一个之上?

是的, 可以安全地将某些电池模块直接彼此堆叠在一起, 但 只有 它们是由制造商专门设计的,用于这种直接的物理堆叠. 这些模块将具有增强的套管和互锁的特征,以确保稳定性和适当的重量分布. 然而, 许多被称为“可堆叠的系统," 像常见的LFP服务器架电池, 实际上是设计为在专用的机架或橱柜内通过货架或轨道单独支撑, 除非设计明确允许它. 始终咨询制造商的规格.

深入潜水: 堆叠的物理注意事项

当考虑将电池模块物理放在彼此上时, 这是重要的:

- 制造商的设计和意图: 这是最重要的. 产品数据表或安装手册将清楚地说明是否允许直接堆叠,并且, 如果是这样, 高多少单位, 以及任何特定的方向或互锁要求. 如果没有提及, 假设没有额外支持的情况下直接堆叠是不安全的.

- 套管强度和承重能力: 专为直接堆叠设计的模块设计了套管,以支撑上方的单元的重量而不畸形或损害内部组件.

- 互锁机制: 许多直接堆叠模块具有物理特征 (例如, 凹槽, 选项卡, 对准别针) 将它们锁定在一起, 防止它们滑动或移动. 这对于稳定至关重要, 特别是在容易振动或地震活动的地区.

- 重量分布: 确保堆栈放置在水平上,并可以支撑总重量.

- 通风和气流: 即使有直接堆叠设计, 制造商帐户需要气流. 确保这些途径没有阻塞. 有些设计可能具有堆叠时对齐的内置空气频道.

- 服务器架电池 - 常见的“堆叠" 例子: GYCX太阳能经常使用的LFP服务器架电池是通常称为“可堆叠的系统”的一个很好的示例。" 当它们物理上一个放在另一个上方 在19英寸的橱柜或架子内, 每个模块通常由自己的轨道或架子支撑. 机架本身提供主要的结构支撑,并确保适当的间距和对齐. 这与旨在直接在外壳上承受全部重量的模块不同.

- 安全第一: 如果有任何疑问,是否可以直接堆叠模块或如何安全地进行操作, 总是 请参阅制造商的官方文件或咨询合格的安装程序,例如GYCX太阳能. 身体不当会导致不稳定, 损害, 和严重的安全危害.

“堆叠锂电池," 尤其是那些使用LifePo₄Chemistry并考虑到模块化和安全性的人, 提供强大而灵活的能源储能方法. 无论您是想通过串联连接增加电压还是通过平行模块来建立容量, 了解设计原则并遵守安全指南至关重要.

在GYCX太阳能, 我们是使用高质量设计和安装可扩展储能解决方案的专家, 安全堆叠的锂电池系统. 如果您对模块化电池库如何满足太阳能或备用电源需求有疑问, 我们邀请您与我们联系. 让我们为您建立弹性的能量未来, 一次堆积良好的模块.

了解与电池相关的术语,例如电池管理系统,以更好地比较锂电池相关的数据概念. 这将帮助您选择一种更适合您需求的产品. ↩