Kuinka aurinkopaneelit valmistetaan

Aurinkopaneeleista on tullut kestävän energian symboli ja keskeinen toimija globaalissa siirtymisessä kohti puhtaampia energianlähteitä. Nämä tyylikkäät, suorakaiteen muotoiset laitteet muuttavat auringonvalon hiljaa sähköksi, mutta oletko koskaan miettinyt, kuinka ne tehdään? Liity mukaan kiehtovalle matkalle aurinkoteknologian maailmaan, kun paljastamme aurinkopaneelien luomisen monimutkaisen prosessin.

1. Aurinkokenno – paneelin sydän

Jokaisen aurinkopaneelin ytimessä on aurinkokenno, kutsutaan usein aurinkosähköksi (PV) solu. Nämä kennot on pääasiassa valmistettu piistä, monipuolinen ja runsas materiaali. Valmistusprosessi alkaa piin puhdistuksella, poistamalla epäpuhtaudet parhaan tehokkuuden varmistamiseksi.

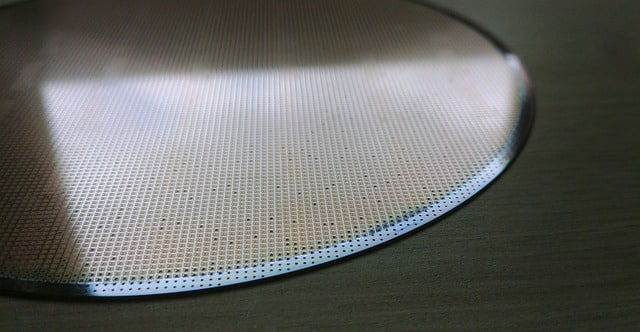

2. Harkot ja vohvelit

Kerran puhdistettu, pii sulatetaan ja muotoillaan suuriksi sylinterimäisiksi harkoiksi. Nämä harkot leikataan sitten erittäin ohuiksi kiekoiksi, tyypillisesti vähemmän kuin 200 mikrometriä paksu. Nämä kiekot toimivat aurinkokennojen substraattina.

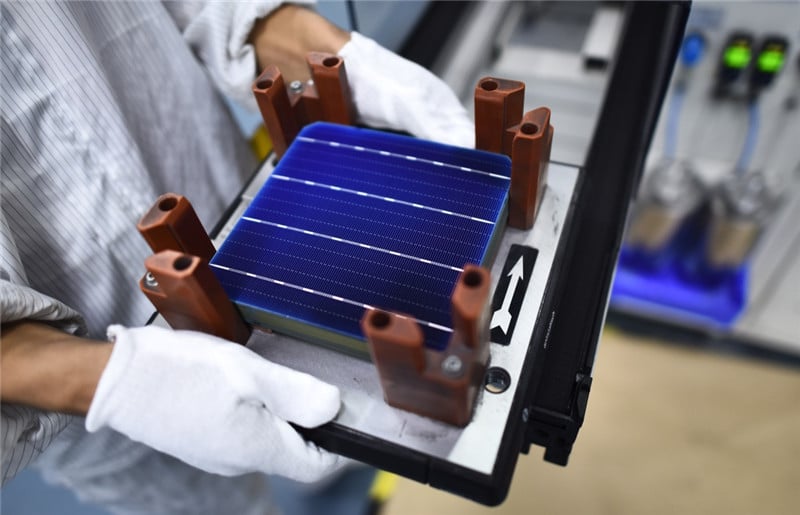

3. Aurinkokennojen tuotanto

Kiekot käyvät läpi tiukan prosessin muuttaakseen niistä toimivia aurinkokennoja. Fosfori diffundoituu kiekon yläkerrokseen, kun taas boori diffundoituu pohjakerrokseen, puolijohderakenteen luominen. Heijastamaton pinnoite levitetään valon heijastuksen minimoimiseksi, maksimoi auringonvalon imeytyneen määrän.

4. Solujen yhteenliittäminen

Aurinkokennot on yleensä kytketty yhteen tietyllä mallilla aurinkomoduulin muodostamiseksi. Johtavia metallinauhoja käytetään solujen yhdistämiseen, mahdollistaa sähkövirran niiden välillä. Tämä kytkentäprosessi on ratkaisevan tärkeä tehokkuuden ja luotettavuuden kannalta.

5. Kapselointi

Suojaa herkkiä aurinkokennoja elementeiltä, ne asetetaan karkaistun lasin ja polymeeripohjan väliin. Karkaistu lasi on uskomattoman kestävää ja tarjoaa erinomaisen suojan säältä, kun taas taustalevy estää kosteuden tunkeutumisen moduuliin.

6. Kehys ja kytkentärasia

Kapseloidut aurinkokennot sijoitetaan sitten tukevaan alumiinirunkoon. Tämä runko tarjoaa rakenteellista tukea ja helpottaa aurinkopaneelin asennusta. Lisäksi, kytkentärasia on kiinnitetty paneelin takaosaan, mahdollistaa useiden paneelien liittämisen ja sähkökaapeleiden reitityksen.

7. Laadunvalvonta ja testaus

Ennen kuin poistut tuotantolaitokselta, jokainen aurinkopaneeli käy läpi tiukan laadunvalvonnan ja testauksen. Tämä sisältää sen sähkötehon mittaamisen, tarkastusta vikojen varalta, ja varmistaa, että se täyttää alan standardit. Nämä testit läpäisevät paneelit ovat valmiita asennettavaksi.

8. Asennus ja integrointi

Kun aurinkopaneelit on valmistettu, ne kuljetetaan asennuskohteisiin. Aurinkopaneelit voidaan asentaa kattoille, aurinkotiloilla, tai osana integroituja rakennussuunnitelmia. Ne on sijoitettu sieppaamaan mahdollisimman paljon auringonvaloa, yleensä etelään päin maksimaalisen tehokkuuden saavuttamiseksi.

9. Tuottaa puhdasta energiaa

Asennettuna, aurinkopaneelit alkavat muuntaa auringonvaloa sähköksi aurinkosähkövaikutuksen kautta. Kun auringonvalo osuu aurinkokennoihin, se kiihottaa elektroneja, sähkövirran luominen. Tämä tasavirta (DC) muunnetaan sitten vaihtovirraksi (AC) invertterin toimesta, tekee siitä käyttökelpoisen kodin sähkönsyöttöön, yrityksille, ja ruudukko.

Aurinkopaneelit ovat kulkeneet pitkän tien perustamisestaan lähtien, ja tekniikan kehitys parantaa edelleen niiden tehokkuutta ja kohtuuhintaisuutta. Kuten todistamme aurinkoenergian yleistyvän maailmanlaajuisesti, Aurinkopaneelien valmistustapa auttaa meitä arvostamaan innovaatiota, tarkkuutta, ja omistautumista näiden ympäristöystävällisten sähkögeneraattoreiden valmistamiseen. Kiehtova matka aurinkoteknologiaan korostaa näiden paneelien roolia hiilijalanjälkemme pienentämisessä ja kestävämmän tulevaisuuden muovaamisessa.

Ota meihin yhteyttä kautta whatsapp/ sähköposti, tai täytä lomake, Ja otamme sinuun yhteyttä mahdollisimman pian