O que as baterias empilhadas fazem?

Você está olhando para a construção de um sistema de armazenamento de energia robusto e encontra a idéia de "empilhar baterias"? Você pode estar se perguntando o que exatamente isso alcança e como funciona. Essa abordagem modular tem tudo a objetivo de fornecer flexibilidade e escalabilidade para atender às suas necessidades específicas de energia e energia, especialmente para sistemas solares ou de backup.

Essencialmente, empilhamento de baterias - quando se referir ao moderno, unidades modulares especialmente projetadas, frequentemente usando fosfato de ferro de lítio (LFP) Química - permite aumentar sistematicamente sua capacidade total de armazenamento de energia (kWh) Ao conectar eletricamente módulos em paralelo. Em algumas configurações específicas, Também pode ser usado para aumentar a tensão geral do sistema, conectando módulos em série. É um método que oferece um espaço eficiente em termos de espaço, organizado, e solução escalável para construir uma reserva de energia que atenda perfeitamente às suas demandas em evolução.

No Gicx Solar, nosso Empilhando produtos de bateria, Como os populares módulos de rack de servidor LFP de 48V, estão no centro de muitos de nossas soluções de energia solar personalizadas. Eles fornecem aos nossos clientes o poder de começar com o que precisam e expandir mais tarde. Vamos explorar o que esse "empilhamento" é tudo sobre.

O que é uma bateria de pilha?

Você já ouviu o termo "pilha de bateria" ou "bateria empilhável." Isso é apenas qualquer coleção de baterias colocadas juntas, ou isso se refere a um mais específico, tipo de sistema projetado? Compreender esta definição é a chave para apreciar o design moderno de armazenamento de energia.

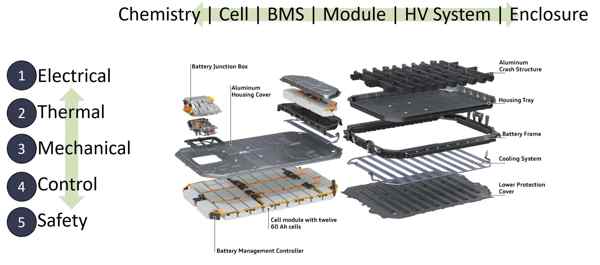

A "Bateria de pilha" sistema (ou bateria empilhável) é composto de módulos de bateria individuais que são Projetado especificamente pelos fabricantes para serem fisicamente colocados juntos em um arranjo estável (diretamente empilhado se projetado para isso, ou instalado em um rack ou gabinete dedicado) e então eletricamente interconectado para funcionar como um único, Banco de baterias maior. Cada módulo nesse sistema normalmente contém sua própria matriz de células de bateria (Frequentemente, LFP-íon de lítio para segurança e longevidade), um sistema de gerenciamento de bateria integrado (BMS) para proteção e monitoramento, e terminais ou conectores construídos para fins específicos que facilitam a ligação fácil e segura a outros módulos. A idéia principal é a modularidade para construir uma solução de armazenamento de energia personalizada e escalável.

Mergulhe mais fundo: Projetado para sinergia

O conceito de "bateria de pilha" O sistema gira em torno de vários princípios de design -chave:

- Modularidade: Cada unidade de bateria é padronizada, módulo independente. Isso é fundamental porque permite que os usuários comecem com uma capacidade que atenda às suas necessidades e orçamento iniciais, e então adicione módulos mais idênticos posteriormente se seus requisitos de energia crescerem. Este "pagamento como você" A abordagem é altamente valorizada.

- Projetado para integração física: Esses módulos não são apenas blocos soltos. Eles geralmente aparecem:

- Invólucros interligados: Alguns designs permitem que os módulos cliquem com segurança ou travem um ao outro quando empilhados diretamente.

- Dimensões padronizadas: Muitos, como baterias de rack de servidor, são construídos para se encaixar com precisão em racks de 19 polegadas ou gabinetes personalizados, garantindo um puro, compactar, e montagem estável.

- Interconexão elétrica projetada: Terminais e conectores são projetados para vinculação elétrica segura e eficiente, seja em série (para aumentar a tensão) ou, mais comumente para expansão da capacidade em uma tensão definida, em paralelo. Isso geralmente envolve barramentos robustos ou cabos de calibre pesado.

- Sistema de gerenciamento de bateria integrado (BMS) por módulo: Esta é uma marca registrada de baterias de lítio empilhável modernas. Cada módulo normalmente tem seu próprio BMS que monitora a saúde das células, protege contra sobrecarga/descarga, sobre corrente, e temperaturas extremas, e executa o equilíbrio de células. Essas unidades BMS individuais geralmente se comunicam com um controlador mestre ou com o inversor do sistema para garantir que todo o banco multimódulo opere harmoniosamente e com segurança.

O propósito é claro: Para criar um maior, personalizado, gerenciável, e sistema de armazenamento de energia escalável de blocos de construção padronizados. Isso é muito diferente de simplesmente acumular baterias não relacionadas, o que seria inseguro e ineficiente.

Tudo bem empilhar baterias umas sobre as outras?

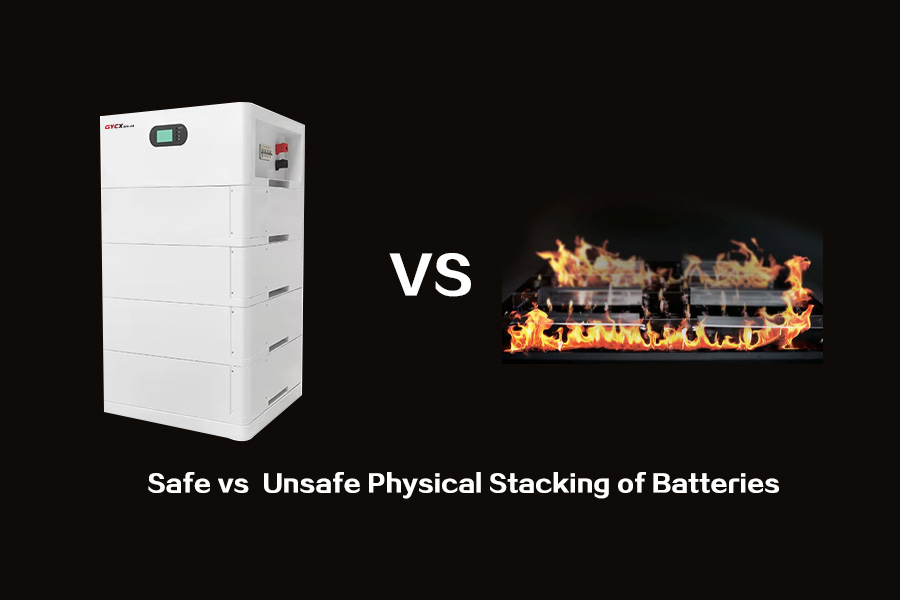

A segurança é fundamental ao lidar com qualquer forma de armazenamento de energia. Então, Quando falamos sobre "empilhamento de baterias," particularmente colocando -os um em cima de outro, Esta é uma prática segura, ou existem riscos inerentes envolvidos?

Isso é Ok e seguro para empilhar os módulos de bateria diretamente um no outro Somente se Eles são projetados e certificados especificamente pelo fabricante para um empilhamento físico direto. Esses módulos criados para propósitos terão recursos como reforçados, invólucros interligados para garantir a estabilidade mecânica, distribuição de peso apropriada, e terá contabilizado o gerenciamento térmico (fluxo de ar) entre unidades. O empilhamento arbitrariamente de baterias não projetadas para isso - especialmente tipos ou tamanhos diferentes - é perigoso e pode levar à instabilidade, curtos circuitos, superaquecimento, e dano. Sempre siga estritamente as diretrizes de instalação do fabricante.

Mergulhe mais fundo: A importância do design para empilhamento seguro

Os fabricantes que projetam baterias a serem empilhados consideram diretamente vários aspectos críticos de segurança e estrutura estrutural:

- Força de revestimento e design: O revestimento da bateria deve ser robusto o suficiente para suportar o peso dos módulos empilhados acima dela sem deformar, rachadura, ou comprometer os componentes internos. Recursos entrelaçados (sulcos, guias, etc.) são frequentemente incorporados para impedir que os módulos mudem ou deslizem.

- Limites de peso: Sempre haverá um limite especificado pelo fabricante em quantas unidades podem ser empilhadas com segurança diretamente. Exceder isso pode levar à instabilidade e falha estrutural.

- Ventilação e gerenciamento térmico: Os módulos de empilhamento juntos podem restringir o fluxo de ar e a armadilha gerada durante o carregamento e descarga. Projetos destinados ao empilhamento direto devem explicar isso, Talvez com canais de ar embutidos, Requisitos de espaçamento específicos, ou usando químicas (Como LFP) que têm melhor estabilidade térmica. A ventilação obstruída é um sério risco de segurança.

- Centro de gravidade e estabilidade: De forma alguma, pilha estreita pode se tornar instável. As dimensões gerais e como o peso é distribuído são cruciais. A superfície em que estão empilhados também deve estar nivelada e capaz de apoiar o peso total.

- Baterias de rack de servidor - um comum "empilhado" Abordagem: Muitos dos "empilháveis" Baterias de lítio GYCX Solar trabalha com, como os módulos de rack de servidor LFP, são projetados para serem "empilhados" verticalmente dentro de um rack ou gabinete de equipamentos de 19 polegadas. Neste cenário comum, Cada módulo é normalmente suportado por seu próprio conjunto de trilhos ou uma prateleira dentro do rack. Enquanto estão fisicamente organizados um acima do outro, O rack fornece o suporte estrutural primário, garantir a colocação segura e espaçamento adequado para o fluxo de ar. Isso é diferente dos módulos projetados para suportar todo o peso dos outros diretamente em suas carcaças.

História solar Gycx: Sempre enfatizamos para nossos clientes que "empilhável" não significa "bateria, de qualquer maneira. 'Por exemplo, Ao instalar as baterias do rack do servidor LFP, Utilizamos sistemas de rack certificados que garantem que cada módulo ~ 5kWh seja adequadamente suportado e tenha ventilação adequada. É essa atenção ao empilhamento projetado que garante a segurança e o desempenho ideal para o armazenamento de energia solar."

Como funciona as baterias de empilhamento?

Qual é o princípio subjacente que torna o empilhamento de baterias eficazes? Como esses módulos individuais combinam seu poder e energia para funcionar como um maior, unidade coesa? "Empilhando baterias" funciona através de uma combinação de inteligente Design físico Para um arranjo seguro e preciso Interconexão elétrica Para alcançar as características desejadas do sistema.

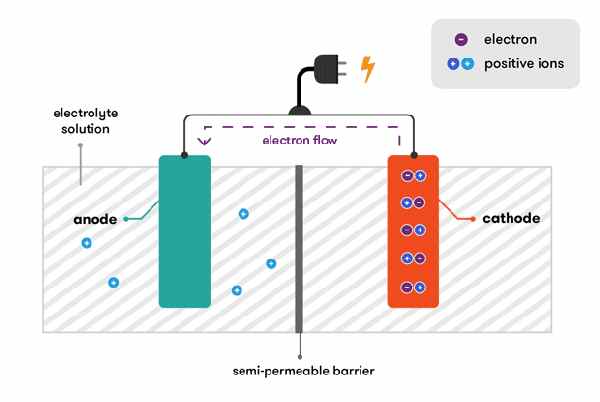

Fisicamente, As baterias empilháveis são projetadas para estável, Conjunto eficiente em termos de espaço, seja através de cartuchas interligadas ou encaixando -se em racks padronizados. Eletricamente, Esses módulos são então conectados de uma das duas maneiras principais:

- Em série: Para Aumente a tensão total do banco de baterias, mantendo a capacidade do amp-hora (de uma única corda) o mesmo.

- Em paralelo: Para Aumente a capacidade total de amp-hora (e, portanto, total energia armazenada em kWh) e capacidade de entrega atual, mantendo a tensão da mesma forma que um único módulo.

Os sistemas integrados de gerenciamento de bateria (BMS1. ) Dentro de cada módulo desempenham um papel crucial no monitoramento e na proteção de suas respectivas células, e frequentemente se comunica ou um inversor/controlador central para gerenciar toda a "pilha" coesamente.

Mergulhe mais fundo: A sinergia do projeto físico e elétrico

Vejamos os dois aspectos:

- Arranjo físico:

- Empilhamento direto (se projetado): Módulos se encaixam com segurança, frequentemente com recursos de alinhamento.

- Montagem de rack (Comum para baterias de rack de servidor LFP): Os módulos deslizam para racks padronizados de 19 polegadas em trilhos ou prateleiras, permitindo alta densidade, Cabamento organizado, e fluxo de ar gerenciado. Esta é uma maneira muito comum e robusta de "empilhar" baterias para sistemas de armazenamento de energia.

- Gerenciamento térmico: O arranjo físico deve permitir que o calor gerado durante a operação se dissipe. Isso é considerado no design dos módulos e em qualquer gabinete fechado.

- Interconexão elétrica:

- Conexão em série (Empilhamento de tensão): Como coberto antes, Módulos de conexão de somas positivas para negativas suas tensões. Isso pode ser feito para atender aos requisitos de tensão de entrada de um inversor ou carga específica. A capacidade de amp-hora da sequência da série é limitada à do menor módulo individual da string.

- Conexão paralela (Empilhamento de capacidade): Conectar todos os terminais positivos e todos os terminais negativos mantém a tensão da mesma forma que um único módulo, mas resume suas capacidades de amp-hour. Este é o método mais comum para ampliar o armazenamento total de energia (kWh) Em sistemas como bancos de bateria de rack de servidor LFP de 48V para energia solar. Se você tiver três módulos de 48V 100AH em paralelo, você recebe um banco 48V 300AH.

- Papel do BMS em uma pilha:

- Proteção de módulo individual: Cada BMS protege suas próprias células.

- Comunicação (Muitas vezes): Em sistemas sofisticados, As unidades BMS podem se comunicar com o inversor (Por exemplo, via Can Bus ou Rs485). Este "circuito fechado" A comunicação permite que o inversor otimize o carregamento com base no status da bateria em tempo real (tensão, temperatura, estado de carga do BMS), o que é vital para a saúde e a longevidade das baterias de lítio. Também permite o monitoramento preciso do sistema.

A maneira como empilhar "funciona" Para a maior parte do modular de Gycx Solar Empilhando produtos de bateria (Como nossas baterias de rack de servidor LFP de 48V) é paralelo a esses módulos de 48V para alcançar o armazenamento desejado de quilowatt-hora. O empilhamento físico em um rack torna a instalação compacta, organizado, e fácil de atender.

As baterias de íon de lítio podem ser empilhadas?

Você provavelmente está considerando a tecnologia de íons de lítio por suas muitas vantagens, como densidade energética e vida de bicicleta. Uma questão -chave então se torna: Esta química avançada de bateria é adequada para esses modulares, configurações empilhadas?

Sim, absolutamente. Muitas baterias de íon de lítio são projetadas especificamente e ideais para empilhar, com fosfato de ferro de lítio (LFP ou LIFEPO₄) -que é um tipo de bateria de íon de lítio-sendo uma escolha particularmente popular e excelente para essas aplicações. As características de segurança inerentes à LFP, sua longa vida de bicicleta, e a facilidade com que sofisticados sistemas de gerenciamento de bateria (BMS) pode ser integrado para tornar as baterias LFP modulares perfeitas para criar sistemas de armazenamento de energia empilhados confiáveis e escaláveis para solar, backup, e uso fora da rede.

Mergulhe mais fundo: A adequação do íon de lítio para empilhar

Aqui está por que a tecnologia de íons de lítio, Especialmente LFP, Funciona tão bem em designs empilháveis:

- Alta densidade de energia (Em relação às químicas mais antigas): As baterias de íons de lítio podem armazenar mais energia em um determinado espaço e peso em comparação com tecnologias mais antigas, como o chumbo-ácido. Isso os torna práticos para criar compactos, sistemas empilhados de alta capacidade.

- Vantagens de química da LFP para empilhamento:

- Segurança: A LFP é conhecida por sua estabilidade térmica e resistência a fuga térmica, um fator de segurança crítico quando os módulos são agrupados de perto.

- Ciclo de vida longo: As células LFP podem suportar milhares de ciclos de carga/descarga, Alinhando-se perfeitamente com a natureza de investimento de longo prazo do armazenamento de energia escalável.

- Robustez: Eles lidam bem com descargas profundas e geralmente têm uma tolerância a temperatura operacional mais ampla do que algumas outras químicas de lítio, Embora as temperaturas ideais ainda sejam preferidas.

- Integração sofisticada do BMS: Baterias de íon de lítio exigir um BMS para operação segura e ideal. Os módulos modernos de lítio empilhável têm unidades BMS avançadas integradas no nível do módulo. Essa gestão granular é essencial ao combinar vários módulos em um banco maior, garantir que cada módulo e suas células sejam protegidas e equilibradas.

- Modularidade por design: Os fabricantes estão cada vez mais projetando baterias de íons de lítio (Especialmente LFP) com modularidade como um recurso central. Isso inclui:

- Fatores de forma padronizados (como unidades de rack de servidor).

- Pontos de conexão elétricos fáceis de usar e seguros para série ou fiação paralela.

- Protocolos de comunicação para interação BMS com inversores e outros módulos.

- Exemplos: O 48V Baterias de lítio de montagem em rack que a solar GYCX frequentemente utiliza é um excelente exemplo. Estes são módulos de íons de lítio LFP projetados para serem facilmente instalados em racks, conectado em paralelo para construir grandes capacidades de armazenamento. Muitos sistemas modernos de bateria de parede residencial também usam lítio em um modular, embora muitas vezes proprietário, design empilhável ou expansível.

É importante distinguir isso de arbitrariamente empilhar células soltas de íon de lítio (Como 18650s ou células de bolsa não em um módulo de proteção com um BMS). Isso seria extremamente perigoso. Sempre use a bateria módulos que são projetados especificamente pelo fabricante para empilhamento e interconexão.

"Empilhando baterias," Quando feito com unidades modulares de íons de lítio construídos como propósito como LFP, é uma maneira poderosa de criar flexível, escalável, e sistemas de armazenamento de energia eficientes. Ele permite que você adapte sua capacidade de armazenamento ou tensão às suas necessidades exatas e fornece um caminho claro para expansão futura. Segurança, Como sempre, vem do uso de baterias projetadas para esse fim e seguintes as diretrizes do fabricante para instalação.

Se você está interessado em aprender como o Gycx Solar's Empilhando produtos de bateria pode fornecer uma solução de armazenamento de energia personalizada e confiável para sua instalação solar ou necessidades de energia de backup, Entre em contato com nossa equipe especialista. Estamos aqui para ajudá -lo a construir a Fundação Power Perfect.

Aprenda sobre os sistemas de gerenciamento de bateria para comparar melhor e entender os conceitos de dados associados às baterias de lítio. Isso ajudará você a escolher um produto que melhor atenda às suas necessidades. ↩