Have you ever wondered what is powering renewable energy systems, electric vehicles, and so many modern devices? The answer is the battery modular. These modules are the building blocks of large battery systems that provide the necessary energy storage and management for a variety of applications.

In this article, we will delve into what a battery modular is, what components it contains, how it differs from other battery configurations, and the steps on how to assemble the module and battery pack.

What is a battery module?

A battery modular is essentially a set of carefully arranged battery case that are arranged in a specific way to work together as one unit. You can think of it as an intermediate layer in the battery system hierarchy.

While a single cell can store and release energy, combining multiple cells into a single module can significantly increase the total capacity and power output. This modular design not only provides a flexible energy solution, but also makes it easier to build larger, more powerful battery packs.

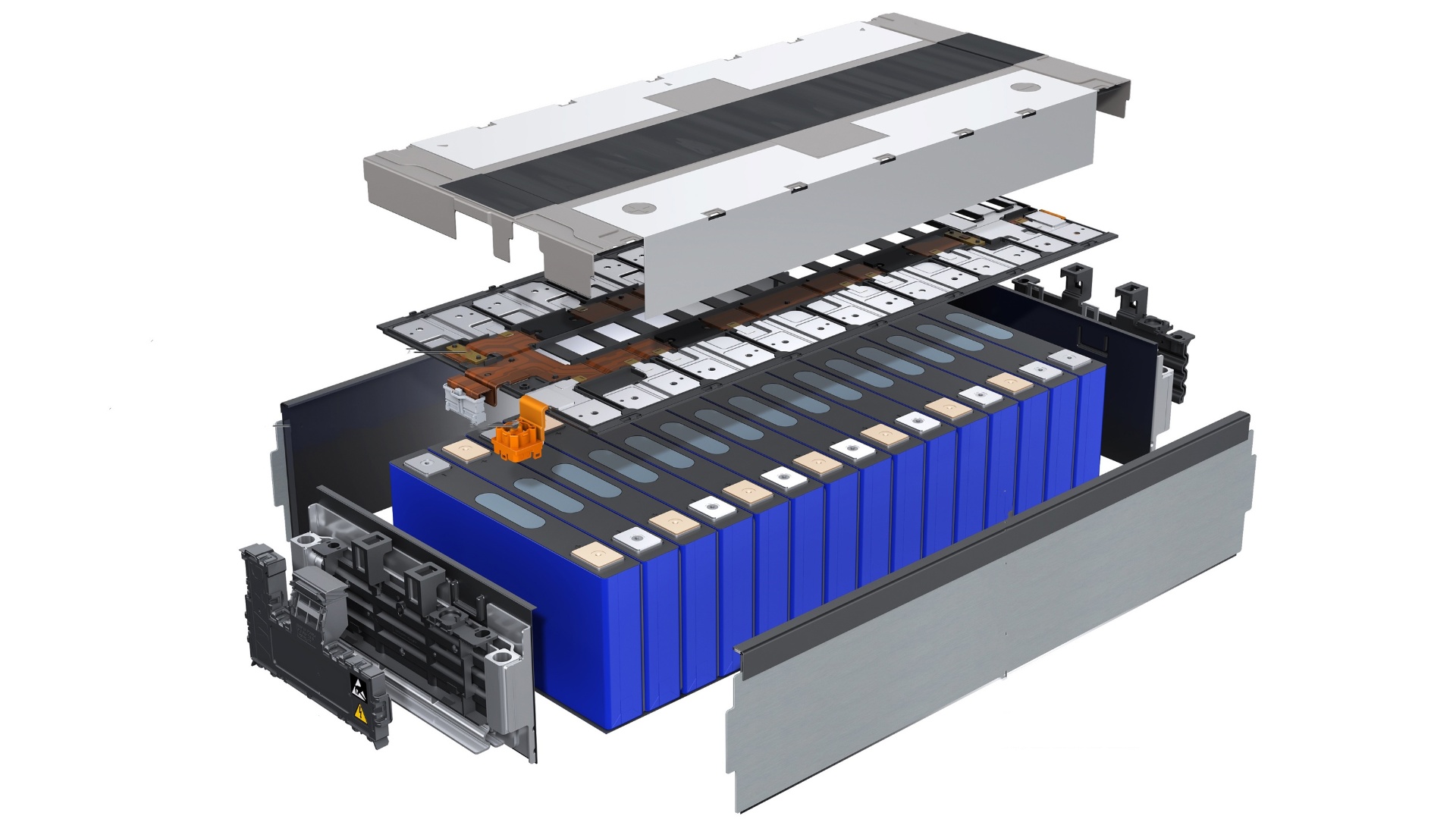

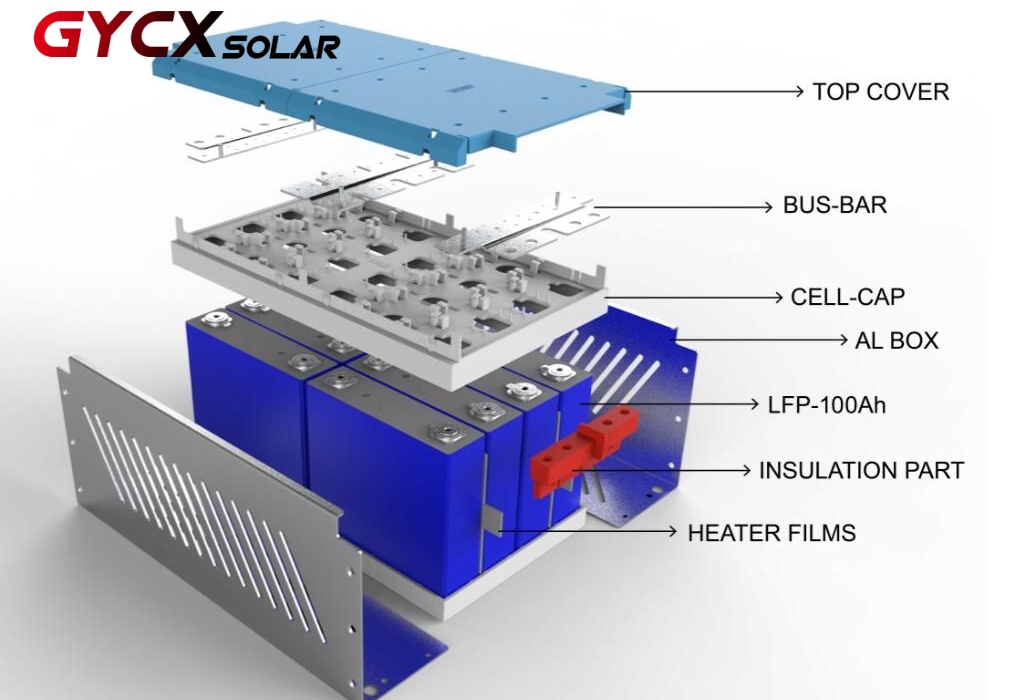

Components of a battery modular

The battery modular is composed of several key components, each of which is critical for its function and safety. Now, let’s break down these components and what they do.

Key components of the battery module:

1. Battery unit

The core of the module consists of a single unit responsible for storing and releasing electrical energy. These are undoubtedly the main energy storage units. They have a wide variety of chemical components, each with its own advantages and disadvantages.

2. Battery Management System (BMS)

The BMS acts as a key component in monitoring and managing the health and performance of the battery case, like the brain of the module. It ensures that the battery is safely charged and discharged, preventing issues such as overcharging, over-discharging and short circuits.

3. Cooling system

Its job is to ensure that the battery maintains the optimal temperature to effectively prevent overheating. The system helps dissipate the heat generated during operation. Proper cooling is essential to maintain efficient operation and long life of the battery.

4. Electrical connection

The wires and connectors that connect the batteries to each other and to external circuits. This includes busbars and connectors that ensure a reliable electrical connection between the battery and the external load.

5.Enclosure

Rugged protective housing that fully protects internal components from physical damage and environmental factors.

The housing has structural integrity that protects the battery and other components from external shocks, dust, moisture, and other environmental hazards.

Why are battery module so important?

The importance of battery modular is that they cleverly strike a balance between manageability and capacity. The capacity of a single battery is too small to meet the power needs of large devices, and the entire battery pack is cumbersome and complex to handle and maintain.

However, the battery modular achieves the right balance. Not only do they increase total capacity, they also simplify the process of designing, assembling and maintaining complex energy storage systems, making it possible to build efficient and flexible energy solutions.

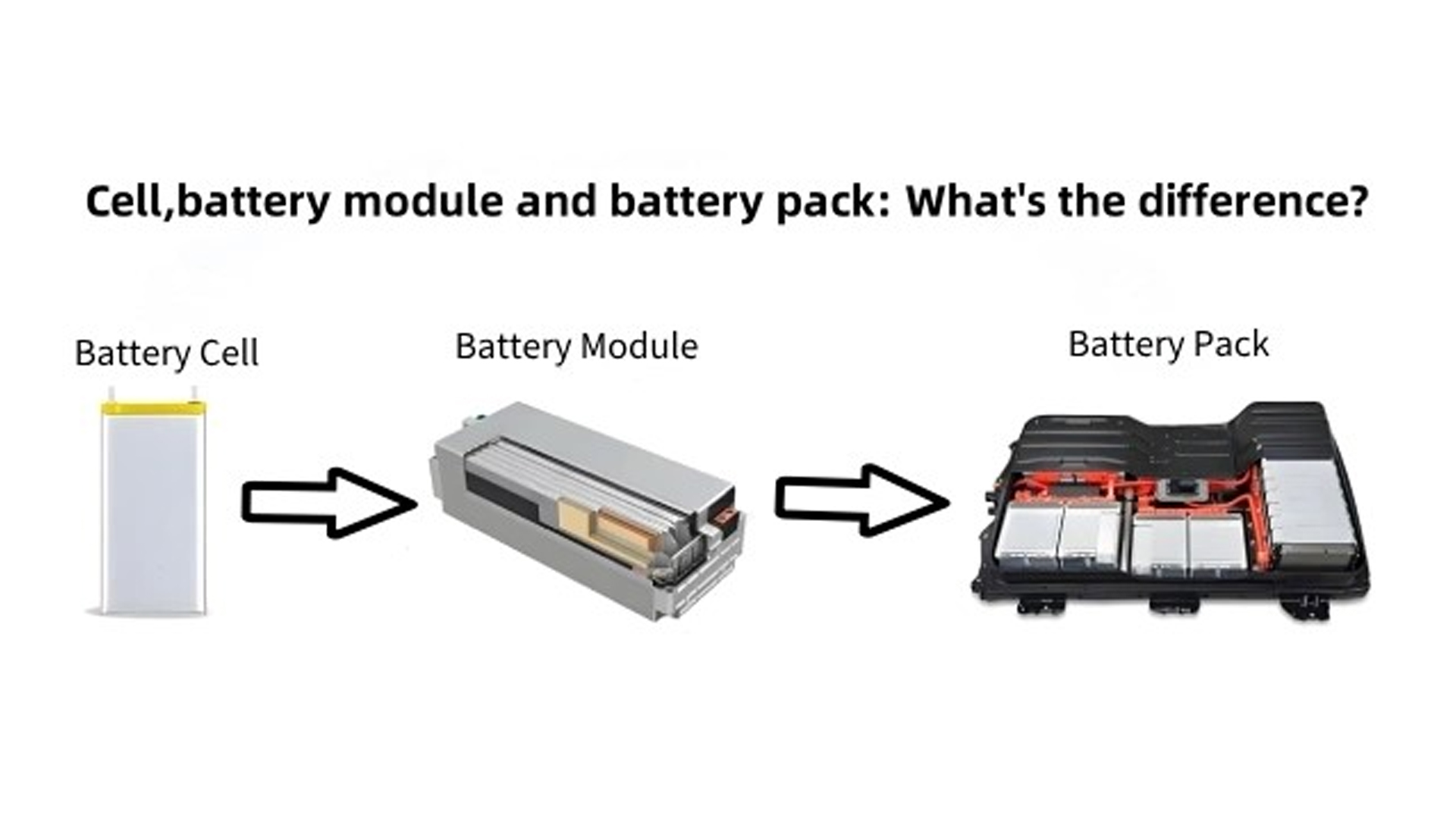

Cell,battery module and battery pack: What’s the difference?

It is crucial for anyone working on energy storage solutions to understand the difference between battery cell, battery module, and battery pack. Although these terms are often used interchangeably, they represent different levels of complexity and functionality.

Battery cell

The smallest and most basic unit of energy storage, capable of storing and releasing energy.

These cell are the basic components of any battery system. They are usually small and have limited capacity. But they are versatile and can be used in applications ranging from smartphones to small electronic devices.

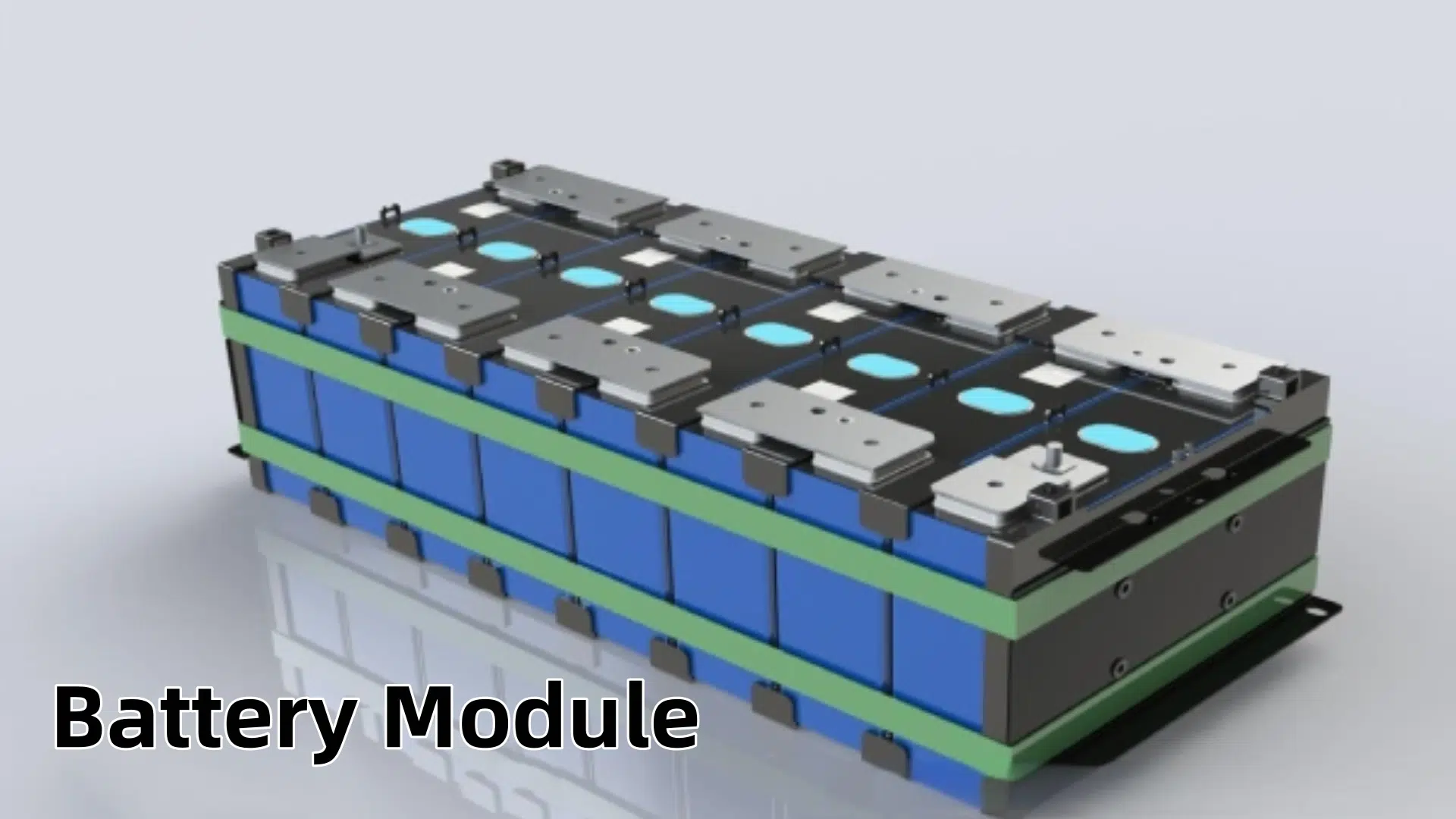

Battery module

Combine multiple battery case into a single unit to provide more energy and capacity. By combining multiple cells together, the battery modular can provide significantly greater energy capacity and output.

The module is designed for manageable size and complexity, making it easier to integrate into a variety of applications, such as electric vehicles and renewable energy systems. The addition of a pool management system (BMS) and cooling system ensures safe and efficient operation.

Battery pack

Multiple modules are assembled to create a more powerful energy storage system.

A battery pack is a collection of multiple battery modular, a configuration that significantly increases energy capacity and power output for large-scale applications such as electric vehicles, grid storage, and backup power systems. Because the battery pack is so complex, advanced management and cooling systems are required to ensure its safe and efficient operation.

How do battery modules form a battery pack?

Once the battery modular is obtained, the next step is to assemble it into a complete battery pack. Here is a step-by-step guide process to guide you specifically:

Module preparation

Make sure all battery modular are fully assembled and tested for performance and safety to ensure they are in top condition.

Design layout

Carefully plan the arrangement of modules in the battery pack. Space, cooling system and wiring requirements need to be considered. The design should balance the load to maximize the efficiency of the system.

Linking module

Electrical connectors are used to connect the modules according to the desired series or parallel configuration. Ensure that each connection point is secure and insulated to prevent electrical hazards.

Install BMS

Install an integrated battery management system (BMS) to manage the entire battery pack. The BMS will monitor the performance of each module to ensure balanced charging and discharging safety.

Additional cooling system

An advanced cooling system is introduced to maintain the optimum temperature of the entire component at all times. Use fans, radiators or liquid cooling systems to effectively control heat dissipation.

Enclose the pack

Secure the assembled module in a sturdy housing. The shell should be both robust and durable, and can effectively resist the invasion of physical impact, dust and moisture. Make sure the housing has adequate ventilation or is directly integrated with a cooling system to support heat dissipation.

How to make a battery module from a battery cell?

Turning from a single battery to a battery modular requires a series of meticulous steps. Here is a detailed step-by-step guide on how to do it:

(1) Collecting materials

Battery cell

Battery Management System (BMS)

Electrical connector (bus, wire)

Cooling components (fan, radiator)

Protective housing (plastic or metal housing)

Tools (soldering iron, multimeter, insulation)

(2) Test unit

Strictly check the voltage and capacity of each battery to ensure that they are within an acceptable range.

Carefully match batteries with similar capacities to maintain balance within the module.

(3) Arrange the units

Design the layout according to the desired configuration (series, parallel, or combination).

Place the battery case in a stand or frame to make sure they are arranged neatly and securely.

(4) Connecting units

Depending on the selected configuration, welding or welding technology, the electrical connector is tightly connected to the battery.

Make sure the connection is strong and well insulated to prevent short circuits.

(5) Install the BMS

Connect the BMS to the module and connect its wires precisely to the appropriate battery terminals.

At this time, BMS will constantly monitor and manage the battery’s voltage, temperature and overall health, carefully caring for every state of the battery.

(6) Add cooling

Implement cooling systems, such as radiators or fans, to properly manage the heat generated during operation.

Ensure that the cooling components are securely connected and precisely positioned for optimal airflow for maximum cooling effect.

(7) Encapsulation module

Gently place the assembled module into the protective housing.

Ensure that the shell is extremely strong and adequately protected against physical damage and environmental factors.

(8) Test module

Perform a rigorous series of tests to verify the module’s performance and security.

Carefully check whether the voltage output is stable, whether the temperature is properly adjusted and whether the overall function is normal, and do not let go of any possible problems.

Conclusion

Battery modular are the cornerstone of modern battery systems, combining individual battery packs into manageable units that provide enhanced energy capacity and safety features. Understanding the composition and assembly process of battery modular is critical to energy storage solutions.

Whether powering renewable energy systems, electric vehicles, or other high-demand applications, knowing how to create and use battery modular can help improve efficiency and safety. Keep these insights in mind the next time you work on a battery project to build a reliable and powerful energy storage system.

If you still want to learn more about batteries, please check out our GycxSolar news!