How Important Is the Battery Bracket?

When planning a battery installation, whether it’s for a small DIY project or a large home energy storage system, we often focus on the battery’s capacity and chemistry. But what about the piece of hardware that holds it all together – the battery bracket or holder? Is it just a simple accessory, or is it a critical component?

The battery bracket is extremely important. It is a foundational component for safety, stability, and longevity. A well-designed bracket provides essential mechanical support, ensures electrical safety by preventing short circuits, helps with thermal management by allowing proper airflow, and guarantees a secure, stable installation. For large, heavy systems like a modern wall-mount battery, the bracket is a non-negotiable, precision-engineered safety device.

At Gycx Solar, we see the mounting system not as an accessory, but as an integral part of the battery solution itself. A great battery is only as reliable as its installation. Let’s explore the crucial role of battery holders and brackets.

What is the purpose of a battery holder?

What does a battery holder or bracket actually do? Is it just for keeping things looking neat and tidy, or does it serve a more critical function?

The primary purpose of a battery holder or bracket is to securely hold one or more batteries in a fixed position, protecting them from physical shock, vibration, and movement. This in turn ensures electrical safety by isolating terminals, prevents damage to the batteries and wiring, and provides the structural foundation for an organized installation with proper airflow for cooling.

Dive Deeper: The Four Pillars of a Quality Bracket

Let’s look at the key functions of a battery bracket, from a small AA holder to a large wall-mount system for a home BESS:

- Mechanical Support and Protection: This is its most obvious job. A bracket prevents batteries from moving around, falling, or being subjected to excessive vibration, all of which can cause internal damage or break electrical connections. For a heavy wall-mount battery, which can weigh over 100 kg, the bracket is an essential piece of structural engineering that safely affixes the unit to the building.

- Electrical Safety: By keeping each battery cell or module in a specific, fixed position, the holder prevents terminals from accidentally touching each other or other conductive surfaces, which would cause a dangerous short circuit. It provides the necessary separation and serves as a non-conductive barrier.

- Thermal Management (Cooling): Batteries generate heat when they charge and discharge. A well-designed bracket or rack system ensures there is adequate space around each battery module for air to circulate. This airflow is vital for dissipating heat and keeping the batteries within their optimal operating temperature. This is especially crucial for battery longevity in a hot, humid climate like Singapore’s.

- Organization and Serviceability: A proper mounting system provides a clean, organized layout. It makes wiring the system easier and safer, and ensures that the batteries are accessible for inspection or service by a qualified technician if ever needed.

A battery bracket isn’t just a piece of plastic or metal; it’s an engineered component that directly contributes to the safety and performance of your entire battery system.

Do battery holders increase voltage?

When you see a battery holder with slots for multiple batteries, you might wonder if the holder itself is doing something electrically to change the output. Does the battery holder increase the voltage?

No, the battery holder or bracket itself does not increase voltage. It is a purely mechanical component designed to hold the batteries. The voltage of the battery bank is only increased by the way the batteries are electrically wired together within the holder or rack. Specifically, voltage increases when you connect batteries in series. The holder simply facilitates these connections.

Dive Deeper: Separating Mechanical and Electrical Functions

It’s essential to understand the difference between the physical holder and the electrical circuit:

- The Holder’s Job (Mechanical): The plastic or metal bracket provides the physical structure. It holds the batteries securely and provides conductive terminals or contacts for you to make your connections.

- The Wiring’s Job (Electrical): How you connect these terminals determines the electrical output.

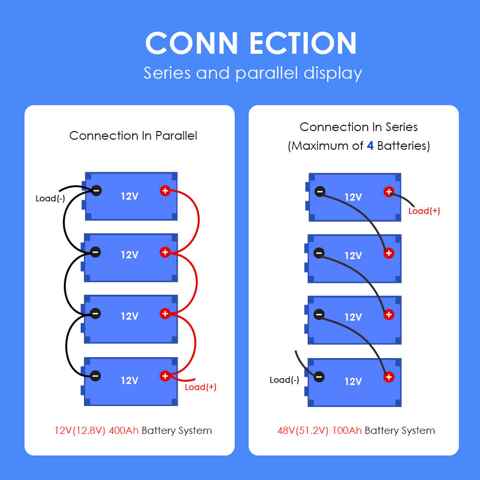

- Series Connection (Increases Voltage): If you connect the batteries positive-to-negative in a chain, their voltages add up. For example, a holder for four 1.5V AA batteries connected in series will produce 6V (1.5V + 1.5V + 1.5V + 1.5V). The holder’s internal contacts are pre-wired to make these series connections automatically.

- Parallel Connection (Increases Capacity): If you were to connect all the positive terminals together and all the negative terminals together, the voltage would remain 1.5V, but the capacity (in mAh) would be four times greater.

This principle applies at all scales. For our large wall-mount battery systems at Gycx Solar, the heavy-duty bracket holds the unit, but it’s the internal wiring and the connection to the inverter that define the system’s electrical characteristics. The bracket itself is passive.

How are battery holders connected?

So if the holder itself doesn’t set the voltage, how are the batteries within it actually connected to achieve a desired outcome?

Battery holders, or more broadly, modules in a battery bank, are connected electrically in one of two fundamental ways:

- In Series: Connecting batteries positive-to-negative to increase the total voltage.

- In Parallel: Connecting batteries positive-to-positive and negative-to-negative to increase the total capacity (in Amp-hours or Ah).

The choice of connection method depends entirely on the requirements of the system you are powering.

Dive Deeper: The Two Ways to Build a Battery Bank

Let’s look at each method:

- Series Connection (for Higher Voltage):

- How: You create a chain, connecting the (+) terminal of the first battery to the (-) terminal of the second, the (+) of the second to the (-) of the third, and so on.

- Result: The voltages add up. The amp-hour (Ah) capacity remains the same as a single battery in the chain.

- When to Use: When you need a higher voltage than a single battery provides. For example, some golf carts or industrial equipment might require a 24V, 36V, or 48V system built from smaller 12V batteries.

- Parallel Connection (for Higher Capacity):

- How: You connect all the (+) terminals together to a single positive lead, and all the (-) terminals together to a single negative lead.

- Result: The voltage remains the same as a single battery. The amp-hour (Ah) capacities add up.

- When to Use: When you are happy with the system voltage but need more energy storage and a longer runtime. This is the most common method for expanding solar energy storage. For example, at Gycx Solar, our wall mount battery or rack mount systems often use multiple 48V battery modules connected in parallel to increase the total kWh capacity for a home.

Gycx Solar Story: "A client wanted longer backup time for their 48V solar system. They already had one of our 100Ah battery modules. The solution was simple: we installed a second 100Ah module and connected it in parallel. This kept the system at 48V but doubled their storage capacity to 200Ah, giving them the extended runtime they needed."

How to place battery in battery holder?

Whether you’re dealing with small household batteries or a large energy storage unit, placing the battery into its holder or bracket correctly is a critical step for safety and proper function.

For small batteries, this means checking for correct polarity (+ and -) and ensuring a secure fit. For large, heavy systems like a professional wall-mount battery, the process is much more involved and should be handled by qualified technicians. It involves securely bolting the bracket to a structurally sound wall and then carefully lifting and locking the heavy battery unit onto the bracket according to the manufacturer’s precise instructions.

Dive Deeper: The Installation Process

Let’s look at the process for a large, professional system:

- Site Assessment and Preparation: A professional installer first identifies a suitable location that is cool, dry, and structurally sound. For a heavy wall-mount battery, this means locating the wall studs or reinforcing the wall to handle the weight, which can exceed 100 kg.

- Mounting the Bracket: The heavy-duty steel mounting bracket is meticulously installed. This involves using a level to ensure it’s perfectly straight and securing it to the wall studs or masonry with the specified heavy-duty lag bolts or anchor bolts. This step is critical for safety – the bracket must be able to support the battery’s full weight without fail.

- Lifting and Securing the Battery: This is always a multi-person job due to the weight. The main battery unit is carefully lifted and precisely hooked onto the wall bracket. Once it’s hanging securely, it’s typically fastened to the bracket with locking screws or clips to ensure it cannot be accidentally dislodged.

- Making Connections: Only after the battery is mechanically secure are the electrical (power) and data (BMS1. communication) cables connected between the battery and the solar inverter.

- Final Checks: The installer performs final checks to ensure everything is secure, correctly wired, and ready for commissioning.

Gycx Solar Story: "Our installation team takes pride in this process. For a recent wall-mount battery installation in a Singapore condo, our team spent the first hour just preparing the wall and perfectly mounting the bracket. A secure bracket is the foundation of a safe system. The client was impressed by the attention to detail, which gave them great confidence in the safety of the system in their home." This professional approach is why you should always rely on certified technicians for installing large battery systems.

The battery bracket or holder is far from a simple accessory; it’s a critical component for the safety, stability, and performance of any battery system. It provides the secure foundation that allows batteries to be connected correctly and operate safely. For modern energy solutions, a professional wall-mount battery system with its engineered bracket represents the pinnacle of safe, space-efficient, and reliable energy storage.

If you have questions about our professional battery storage solutions and how we ensure every installation is secure and optimized for performance, contact our expert team at Gycx Solar today!

Understanding the concept of BMS will help you better compare and understand battery-related data concepts. This will help you select the product that best suits your needs from our company. ↩