Solar panels perform the difficult task of generating solar energy from the sun, but building them in a well-managed factory is fairly simple. Solar panels are made up of solar cells, silicon, metal and glass. Each of these components is then assembled into a solar panel capable of producing sustainable energy.

Let us walk you through the details of how are solar panels made, where are solar panels made and what are solar panels made of before they are delivered by a contractor and installed on your roof.

Where Are Solar Panels Made?

From the United States to Europe, solar panel manufacturers are numerous, but the vast majority of solar panels are made in Asia. In recent years, outsourcing manufacturing to countries with lower labor costs has become standard practice in many industries.

Still, many high-quality panels are produced in the United States, so quality can be tightly controlled at each stage of production.

Let’s examine a few examples of solar panels to understand their production sites. Panasonic and Mission Solar are both premium brands. Panasonic Solar panels are manufactured in the United States and Malaysia, while Mission Solar panels are manufactured only in the United States.

Jinko solar is a cheaper manufacturer of Solar panels than Panasonic or Mission Solar, making solar panels in China. Solar Power is a lesser-known company that makes panels in Canada.

Because supply chains can span multiple countries, all components of a solar panel are not always produced in the same location. While solar panels are manufactured worldwide, there are also many options that are made in the United States.

What Are Solar Panels Made of?

At the most basic level, solar photovoltaic cells, polysilicon or silicon, metal and glass are the key components of solar panels. Solar cells convert sunlight into useful energy and are the most important component. Solar cells are photovoltaic (PV) components of solar panels, which means they produce solar energy.

Solar cells are made of silicon and are shielded by a layer of glass that allows sunlight to filter onto the cell. When exposed to sunlight, the solar silica cell generates an electric current, which is subsequently converted into usable alternating current by an inverter.

Solar cells are built with the help of wires. The wiring is welded to the battery, which is then placed between the protective backplane and the glass. A metal frame holds the entire panel together.

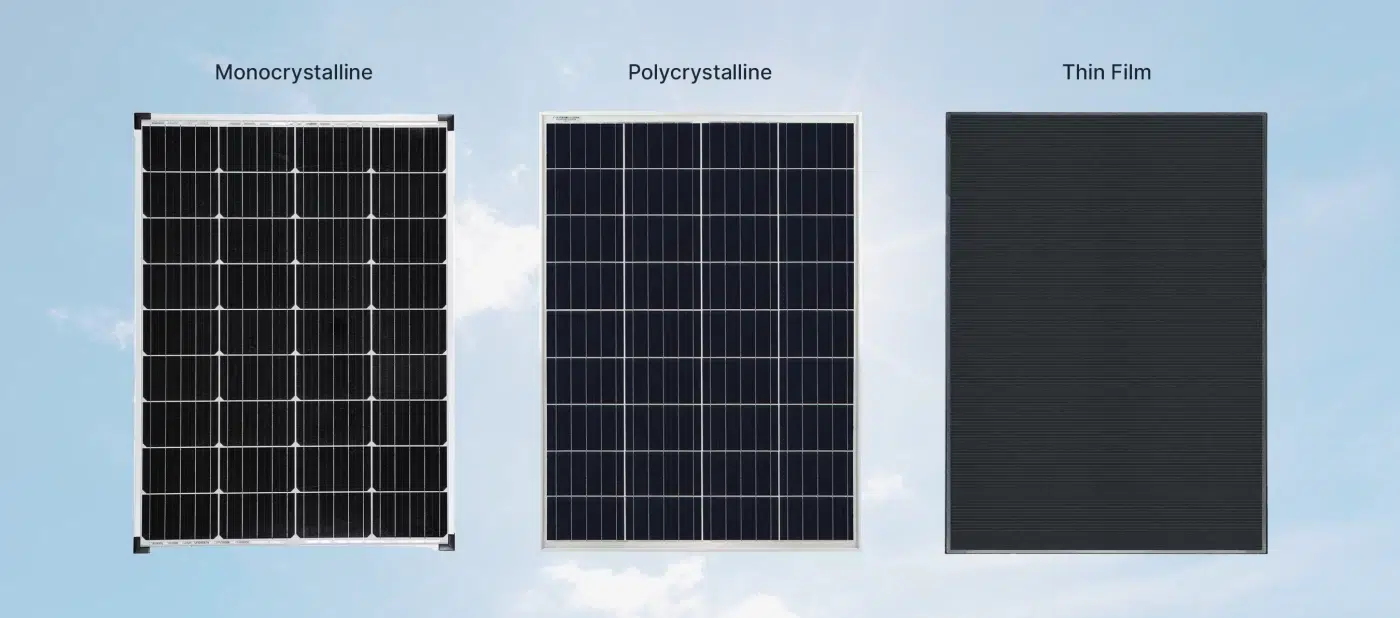

What Are the 3 Types of Solar Panels?

Solar panels are mainly divided into three types: single crystal, polycrystal and thin film.

Single crystal solar cells are cut from single crystals. These crystals are grown from molten silicon by a highly controlled process. The e difference with polycrystalline silicon panels is that polycrystalline silicon panels are made by fusing many silicon crystals together, a process that does not require the growth of single crystals from molten silicon.

Because of the use of monocrystalline silicon, monocrystalline panels are more efficient than polycrystalline panels, but they are also more expensive. The main differences are aesthetic appeal, cost and efficiency, but either option is an excellent choice for a residential solar system.

Due to their very low efficiency, thin film solar panels are mainly used for utility-scale projects within the solar industry. Therefore, a large amount of electricity is needed to generate electricity. Unlike monocrystalline and polycrystalline panels, thin film panels are not composed of solar cells, but are made by depositing a thin layer of photovoltaic material (such as amorphous silicon or cadmium telluride) onto a solid substrate surface (such as glass).

Thin film solar panels are not used in residential solar installations because they are not as strong or efficient as conventional panels.

The technical details of solar panel manufacturing are complex, and we detail each step of the process in the following sections. The following steps apply to crystalline silicon solar panels, which account for more than 90% of the global market. Other panel types, including thin film panels, have different manufacturing processes depending on the material.

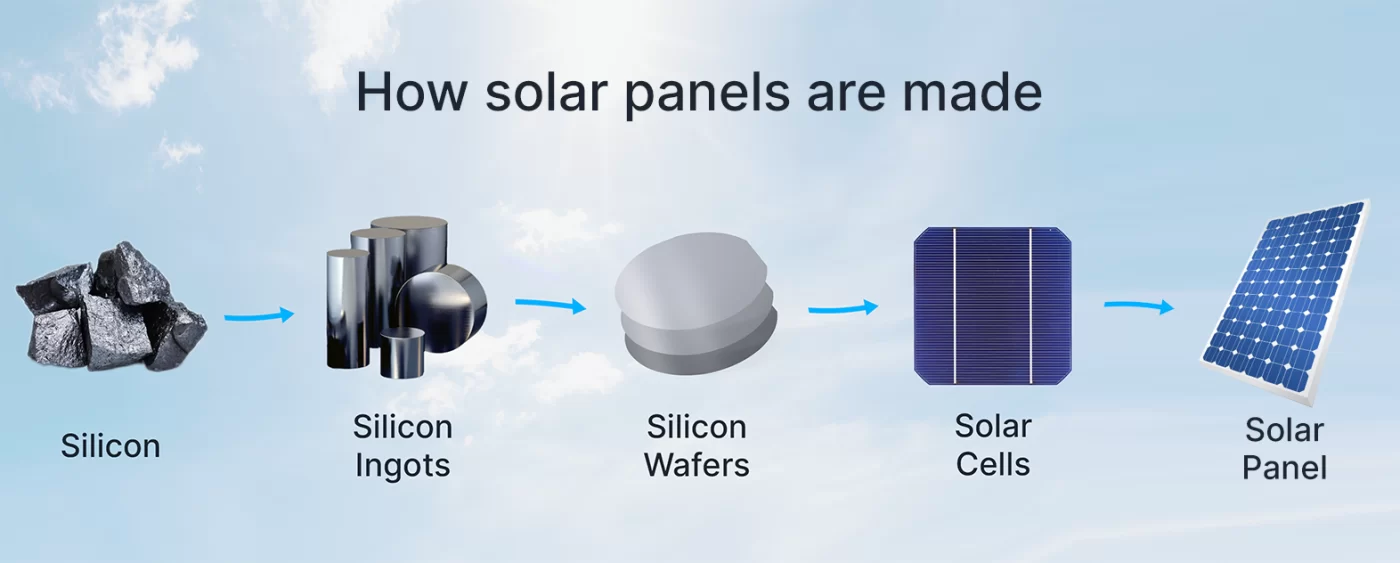

How Are Solar Panels Made?

Step 1: Extraction and Refining of Silicon

Silicon is the second most abundant element in the Earth’s crust, after oxygen, making up 27.7% of the Earth’s crust. However, naturally occurring silicon combines with other elements such as oxygen, phosphorus, and nitrogen. In order to use silicon to generate solar energy, it must first undergo a purification process. At this stage, the silicon takes the form of sand or silica, usually made from crushed quartzite.

The oxygen content in mineral silica can be removed by high temperature, resulting in high purity silicon. The solar industry uses 99.9999% pure polysilicon to make both polycrystalline and single-crystal solar cells. Single-crystal solar panel cells are derived from a single silicon crystal (unlike coffee from a single source), while polycrystalline solar panels use a mixture, resulting in slightly less efficiency.

After the silicon is purified, it is melted in the crucible to form silicon ingot. The ingot now looks like a lump of metal.

Step 2: Cut the Ingot Into Wafers

After the ingot has cooled, it is ground and polished so that the ingot has a flat side. The ingot is cut into chunks using silicon carbide coated wire.

Silicon ingots are cut into thin sheets, also known as wafers, which are about as thin as a sheet of paper. The chips are then cleaned, doped with boron or phosphorus and tested repeatedly.

Because pure silicon is shiny, it reflects sunlight. To reduce sunlight loss, the silicon is coated with an anti-reflective coating.

Step 3: Make the Wafer Into A Solar Cell

After each wafer is treated, metal conductors are added to the surface to form a grid-like matrix on the surface of the wafer, ensuring that solar energy is converted into electricity. The coating will promote the absorption of sunlight rather than reflecting it.

In an oven-like chamber, phosphorus spreads out into thin layers on the surface of the wafer. This will give the surface a negative charge. The combination of boron and phosphorus will form a positive and negative junction, which is essential for the proper function of photovoltaic cells.

Step 4: From Solar Cells to Solar Panels

The solar cells are welded together using metal connectors to connect the cells. Solar panels are made of solar cells integrated together in a matrix-like structure.

After placing the batteries together, add a thin layer of glass (about 6-7 mm) on the front side facing the sun. The back is made of a highly durable polymer material. This will prevent water, soil and other materials from entering the panel from the back. The junction box is then added to enable the connection inside the module.

Step 5: Package and Backplane

Solar cell lamination is a key step in the manufacturing process of solar panels, which are packaged in a two-layer vinyl acetate (EVA) package that helps protect the panels from dust and moisture. EVA is a transparent polymer layer specially designed to hold all solar cells together at the time of manufacturing.

Once all installed and laminated together, the glass and solar cells are mounted into the aluminum frame. The frame provides protection against shock and weather and houses all cables and bypass diodes for protection and interconnect panels.

Solar Panels Testing

Once the module is ready, tests are carried out to ensure that the battery is functioning as expected. Throughout the production process, the materials used to build the panels are checked for defects, such as damaged or deformed solar cells being discarded.

The STC (Standard Test Condition) is used as a reference point and the panel is put into the flash tester at the manufacturing plant. The tester will provide an irradiance equivalent of 1000W/m2, a battery temperature of 25°C and an air quality of 1.5g. Electrical parameters are recorded and you can find these results on the technical specification sheet for each panel.

Solar panels undergo extensive testing to ensure they can withstand extreme weather conditions, high temperatures and typical wear and tear. In addition, it must be verified that the current is flowing efficiently through the panel.

The strength of the solar panels is then assessed to ensure they are least likely to break due to hail or other falling debris. Testing the quality of solar panels is crucial to ensure they can generate electricity and last throughout their service life.

Should You Make Your Own Solar Panels?

We do not recommend building your own solar panels, despite the fact that how are solar panels made and what are solar panels made of may seem simple. The disadvantages of building your own solar panels, such as starting a fire, outweigh their advantages.

Professionally constructed solar technologies are the greatest option because they are manufactured to strict standards and tested for longevity. Dealing with a competent solar installer is essential to ensuring that your solar panels are constructed from high-quality components that will deliver solar power for at least the duration of their 25-year warranty. Solar panels are one of the best energy sources for lowering carbon dioxide emissions from fossil fuels, so installing them in your home is a fantastic way to contribute to the future of clean energy.

Conclusion

From the above, we have already understood how are solar panels made. If you are interested in joining the thousands of homeowners who have switched to renewable energy, contact us today and GYCX Solar can help you take the first step. By getting multiple quotes, you can be confident you’re getting the best price.

Fill out our 1-minute contact form today to start getting a quote from a trusted solar panel installer! This service is completely free and non-binding!